0161 359 8309

Monday - Friday 8am - 5pm

0161 359 8309

Monday - Friday 9am - 5pm

mcr PROLIGHT

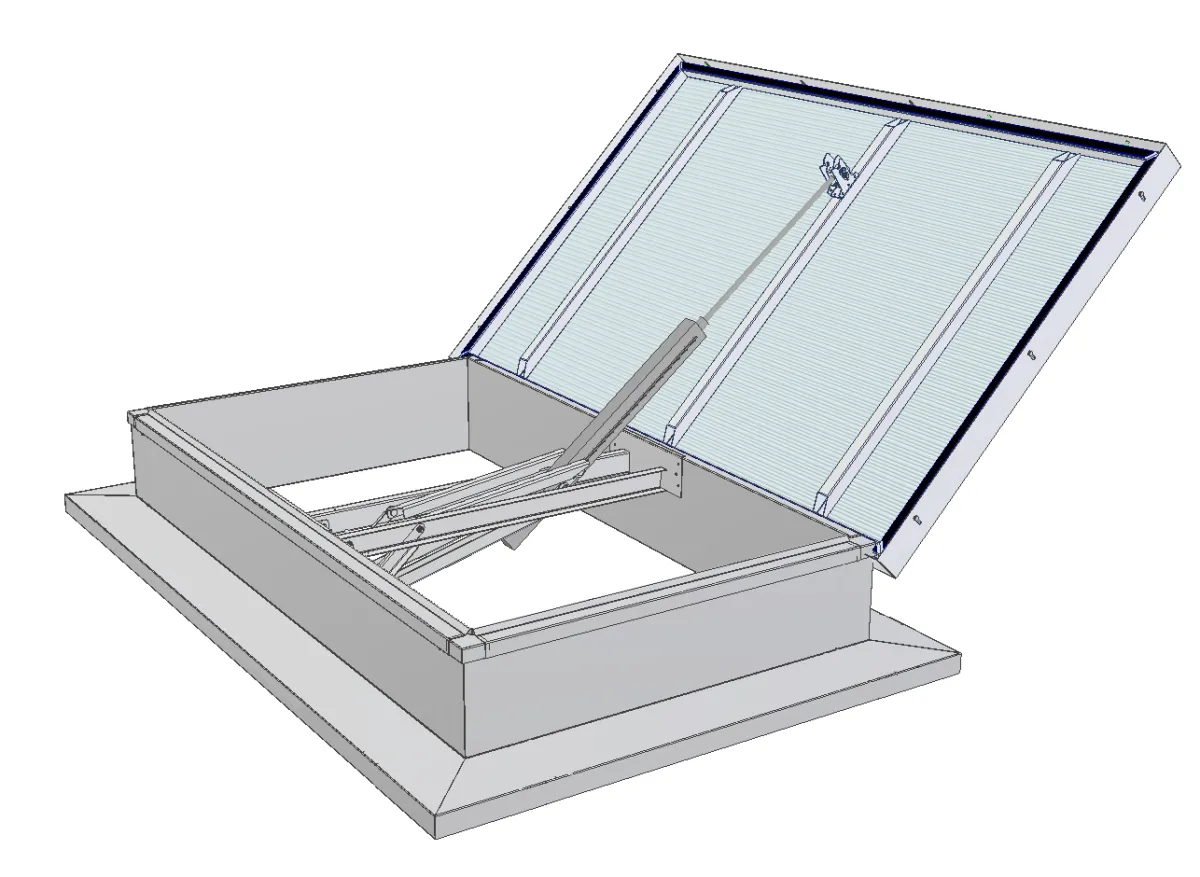

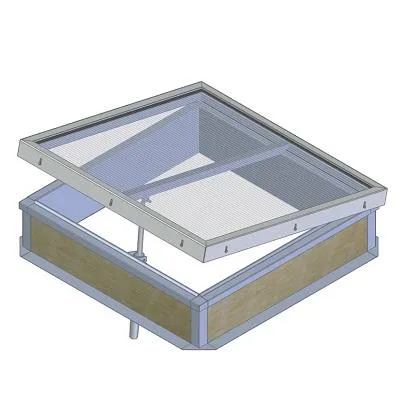

Smoke vents mcr Prolight are automatic smoke exhaust devices.

The basic function of smoke vents mcr Prolight is to exhaust smoke, combustion gases and heat energy from enclosed spaces (production floors, storage spaces, public facilities, etc.) to the outside of buildings, in order to protect human lives and property

CE PARAMETERS ACC. TO EN 1201-2

• Re300 or Re50 – operational reliability during 300/50 cycles of opening and shutting to smoke venting position, and 10 000 cycles to ventilation position (double function vent),

• WL1500 or WL750 – operational certainty of vent under wind stress equivalent to 1500 Pa or 750 Pa (depending on type, size and accessories),

• T(-25) or T(00) – resistance of vent to low temperature of -25°C or 0°C,

• B300 or B600 – resistance of vent to high temperature of 300°C or 600°C (depending on type and accessories),

• SL 250÷950– operational certainty of vent under snow load N/m2

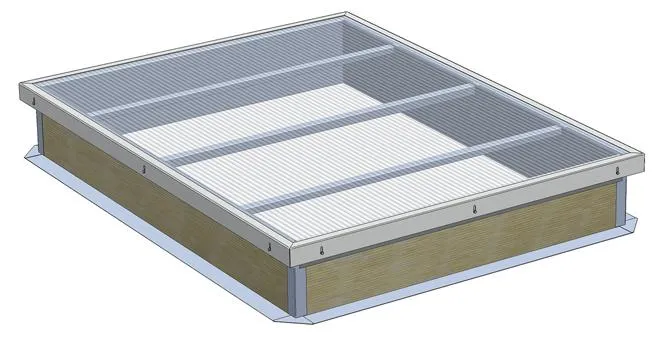

Construction of the product

- leaf filling: multi-chamber polycarbonate panel, acrylic dome, solid polycarbonate domes, panel made of multi-chamber polycarbonate with a 1- or 2-layer dome - acrylic or solid polycarbonate, PIR panel with aluminium cladding

- control: pneumatic smoke exhaust control system, electric 24 V- / 48 V- smoke exhaust control system with ventilation option, pneumatic-electric control system; the pneumatic part is responsible for smoke extraction, the electric part 230 V~ for the ventilation function

- straight base (type C, E) 300 mm ÷ 500 mm high, made of galvanized steel sheet

- skew base (type NG-A) with a height of 300 mm ÷ 500 mm, made of multi-chamber PVC profiles or galvanized steel sheet