0161 359 8309

Monday - Friday 8am - 5pm

0161 359 8309

Monday - Friday 9am - 5pm

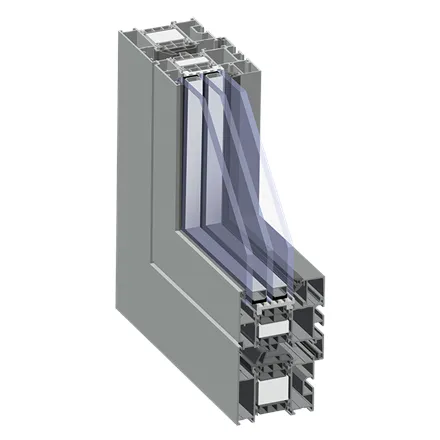

mcr OSO THERM 75 SMOKE EXHAUST WINDOWS

Mcr OSO THERM 75 smoke exhaust windows are a family of innovative products that we developed combining our 30-years’ experience in the natural smoke ventilation market with the expertise of the leading European experts in window profile sector. We designed this solution taking into account the requirements of the changing construction market and the expectations of our customers.

We have additionally designed special grooves in the window profiles facilitating quick, non-invasive assembly and adjustment of drive brackets and cable laying in order to maintain the best aesthetic effect. Universal profile and bracket standardisation make the customer aware from the very beginning what the final solution is going to look like, guarantee easy assembly, ensure favourable delivery times and aesthetic values.

Types

bottom hung opening outward

bottom hung opening inward

top hung opening outward

top hung opening inward

Certificate of constancy of performance 1396-CPR-0128 (according to EN 12101- 2:2003)

- Re1000 - operational reliability during 1000 cycles of opening and closing to smoke exhaust position, and 10 000 cycles to ventilation position (double function window)

- WL1000 / WL1250 / WL1500 - operational certainty of window under wind stress equivalent to 1500 Pa, 1200 Pa or 1000 Pa (depending on type, size and accessories),

- T(00) - resistance of windows to low temperature 0°C

- B300 - resistance of windows to high temperature 300°C

- SL0 - operational certainty of vents under snow load 0 N/m2

Parameters:

- min. nominal dimensions: 800 [mm] x 800 [mm]

- max. nominal dimensions - horizontal arrangement BxH: 2700 [mm] x 1300 [mm]

- max. nominal dimensions - vertical arrangement BxH: 1600 [mm] x 2200 [mm]

• smoke exhaust windows made of custom-designed multi-chamber aluminium profiles with polyamide thermal breaks

• spindle or chain actuator

• profile width: frame 75 mm and leaf 84 mm

• system of grooves in the profile of the leaf and frame with a covering profile allows to route cables and easily install actuator consoles

• leaf glazing: triple glass 4/18/4/18/4 (heat transfer coefficient Ug=0.5W / (m²K)), triple safety glass 4/18/4/18/33.1 (Ug=0.5W / (m²K)), double glass 4/16/33.1 (Ug=1.1W / (m²K)) or sandwich panel (ALU-PIR-ALU) (Ug=0.66W / (m²K))

• windows joined with each other by means of vertical or horizontal connection sets

• leaf opening angle 10° ÷ 90° (depending on the size of the window and type of control used)

• exhaust or daily ventilation control: 24 V- / 48 V- power supply or 230 V~

• use of an electro-lock with interface for the selected dimensional range of smoke exhaust windows with spindle actuators