0161 359 8309

Monday - Friday 8am - 5pm

0161 359 8309

Monday - Friday 9am - 5pm

mcr WIP LD

MERCOR FIRE PROTECTION UK LIMITED - mcr WIP LD

In this article we will take a look at the mcr WIP LD. A multi-blade smoke lobby damper for use in natural and mechanical multi-zone ventilation shafts. Before we go through the product we take a brief look at smoke shafts and the standard that apply to their design and use within multi-storey buildings.

What is a smoke or ventilation shaft used for?

Commonly referred to as ‘smoke shafts’ and positioned in the lobbies of multi-storey buildings. Shafts are used to maintain reasonable conditions in the common escape routes, corridors, stairwells etc. in the event of a fire in the building.

In 2002, research carried out by BRE titled ‘Smoke Shafts Protecting Fire Fighting Shafts, Their Performance and Design’ born smoke shafts as we know them today. The report focused on fire-fighting shafts and proposed natural ventilation, with the outcome coining the phrase the ‘BRE Shaft’.

Developments in smoke shaft over the years has led to a growth in the popularity of mechanically ventilated shafts and these systems are commonly used to warrant escape travel distances that exceed those recommended in Approved Document B (ADB) of the building regs.

This is on the basis that mechanically ventilated shafts offer a higher standard of protection than can be provided by natural ventilation shafts.

Smoke shaft dampers

A damper provided with the required free area to allow the evacuation of air/smoke specified is installed at the point of extract from the lobby into the smoke shaft.

In the event of a fire the damper on the on the effected floor opens to ventilate the lobby. All dampers on other floors remain closed to prevent the spread of smoke between floors.

What is the current guidance for smoke shafts

ADB offers guidance for natural smoke shaft dampers as follows:

Paragraph 3.51iii

All vents (serving a natural smoke shaft) should either be a fire door set (see Appendix C, Table C1, item 2.e for minimum fire resistance), or fitted with a fire and smoke damper (see paragraph 9.21).

Paragraph 9.21

Fire and smoke dampers should meet both of the following conditions:

15650. Conform to BS EN 15650.

15651. Have a minimum ES classification of 60 minutes or to match the integrity rating of the fire resisting elements, whichever is higher.

It is impossible to comply with the conditions specified above as dampers to BS EN 15650 are fitted with a thermal device to automatically close the damper. In a smoke shaft application, the damper on the fire floor is needed to open and such a thermal device could lead to the damper closing and the system failing.

BS 9991:2015 Fire safety in the design, management and use of residential buildings

Code of practice

14.2.3.2 Natural smoke shafts situated above ground level

The lobby or corridor vent, the opening at the head of the shaft and all internal locations (such as safety grilles) within the shaft should have a free area of at least 1.0 m2.

The top of the lobby or corridor vent should be located as close to the ceiling of the lobby or corridor as is practicable and should be at least as high as the top of the door connecting the lobby or corridor to the stairwell.

The lobby or corridor vents, in the closed position, should have a minimum fire and smoke resistance performance of 30 min and integrity (leakage) no greater than 360 m3/h/m2 when tested in accordance with BS EN 1366-2

BS EN 1366-2 is the test standard for fire dampers, smoke control dampers are tested to 1366-10

The use of fire doors with actuators is allowed under ADB but is not a solution recognised by the SCA, as products meeting the requirements of the EN12101 series is advocated.

Other ad hoc tested products or products meeting the requirements of EN 12101-2 are not allowed for allowing smoke to enter a vertical shaft and are not allowed under ADB.

Similarly, the use of fire dampers CE marked to EN 15650 with replaced actuators is not acceptable as the smoke control damper test requires the actuator to be cycled before the fire tests and to be part of the tested smoke control damper assembly.

(NOTE: DW/144 Section 24 advises use of fire damper CE marked to EN 15650 then modified for use in smoke control. This is no longer acceptable as the CE mark is invalid for use as smoke control damper, which has its own CE marking requirements.)

Mcr WIP LD

The Mercor mcr WIP LD multi blade lobby smoke damper is the solution to all the above.

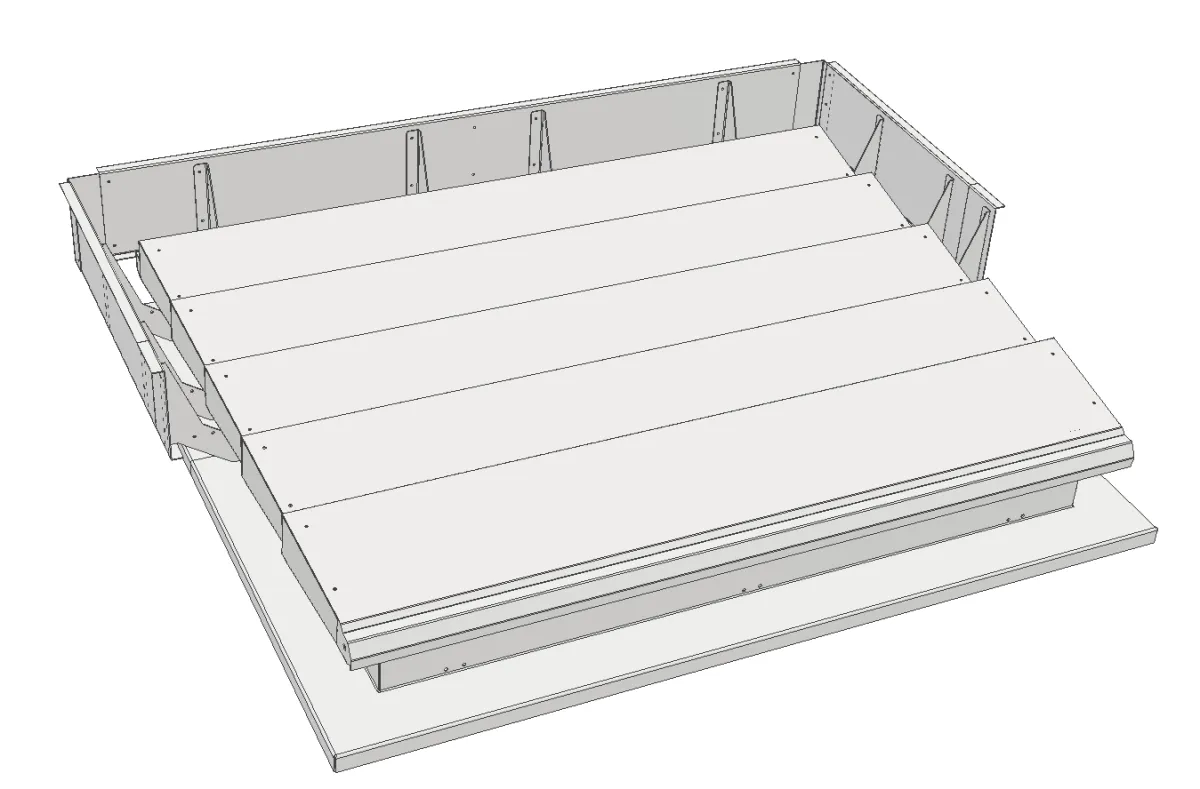

Developed in house by the experienced Mercor S.A. R&D team the mcr WIP LD smoke dampers consist of a casing with a rectangular cross-section, multiple moving damper blades – louvers rotating around their own axes – and a remotely activated trigger and control mechanism, which is installed inside the damper clearance. The damper casing is made of galvanized steel sheets or stainless steel sheets. The damper is also provided with a connection flange on one side. The other end is the so-called “bare-end”. The damper casing total length is 350 mm. Damper louvers are made of galvanized steel sheets or stainless steel. The damper blades revolve on their own axes, which consist of steel pins. A ventilation gasket is provided on the blades to ensure that the damper is “cold” sealed.

The mcr WIP LD smoke dampers are intended for installation in manually or automatically operated fire ventilation systems. The devices are used in fire ventilation systems or in mixed fire and comfort ventilation systems (smoke evacuation or air supply systems). The dampers prevent fire, smoke and fire gases from spreading to the adjacent compartments. During normal system operation, the damper blade is closed. The fire damper blade in the fire compartment is opened, whereas in other areas the blades are closed.

Mercor UK are now carrying stock of the mcr WIP LD to meet natural and machanical shaft requirements