What Is an Actuator? Definition, Types, and Applications Explained

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Imagine being trapped in a building filled with thick, choking smoke—where finding your way out becomes nearly impossible. That’s exactly the danger a smoke ventilation system is designed to fight. These clever systems clear smoke quickly during a fire, making escape routes safer and giving firefighters a better chance to do their job. In this article, we’ll break down what smoke ventilation systems are, how they work, and why they’re essential for keeping people safe when seconds count.

A smoke ventilation system is a critical fire safety solution designed to automatically extract smoke from buildings during a fire, keeping escape routes clear and improving visibility for occupants and firefighters. These systems use natural or mechanical methods to remove hot smoke and toxic gases, reducing heat buildup and helping to control the spread of fire.

At its core, a smoke ventilation system exists to keep escape routes—corridors, stairways, and lobbies—free from the dense, toxic smoke that a fire produces. When a fire breaks out, smoke isn’t just an obnoxious nuisance; it’s one of the deadliest obstacles between people and safety. Toxic gases can overwhelm occupants quickly, visibility drops to near zero, and panic sets in.

These systems act like silent guardians, activated automatically upon smoke detection. They open smoke control vents and doors precisely where needed to extract smoke efficiently, creating clear paths for people to exit unharmed.

The practical impact goes beyond just clearing air—it fundamentally changes survival odds. Studies show effective smoke ventilation can reduce smoke layer temperature by up to 50%, dramatically lowering the risk of heat-related injuries and enhancing breathable air quality.

By pushing hot smoke upward and out, while pulling in fresh air at lower levels, these systems maintain a safer environment during evacuation.

Another essential part is helping firefighters. When they arrive at a fire scene, thick smoke severely hampers their ability to reach victims and control the blaze.

A functional smoke ventilation system thins this invisible enemy, providing better visibility and reducing toxic exposure so firefighters can move faster and safer—a crucial advantage in saving lives and protecting property.

Smoke control also serves a protective role for the building itself. Without ventilation, heat accumulates alongside smoke, increasing chances of flashover—a rapid ignition of all combustible materials in a space—and structural damage.

By expelling smoke and reducing heat concentration, these systems help limit damage extent by roughly 20-40%, which benefits both immediate safety and future repair costs.

| Benefit | Impact |

|---|---|

| Clear Escape Routes | Enables safe evacuation under reduced smoke |

| Reduced Smoke Layer Temperature | Lowers risk of heat-related injuries |

| Improved Air Quality | Minimises toxic gas inhalation |

| Enhanced Firefighter Access | Speeds rescue operations |

| Minimised Structural Damage | Limits fire spread and costly destruction |

For building designers, engineers, or safety managers specifying or maintaining these systems, understanding these layered purposes highlights why compliance with regulations like EN12101 and BS7346-8 is non-negotiable.

It ensures each component—from lobby dampers to Automatic Opening Vents—is selected and installed for optimal performance during emergencies.

With a solid grasp of why these systems are critical in emergencies, it’s time to examine the mechanics behind their operation—how different technologies are deployed to manage smoke effectively across diverse building types.

The core function of a smoke ventilation system lies in managing smoke’s movement and removing it swiftly to keep escape routes safe and breathable during a fire. When smoke is detected, the system springs into action—its sensors trigger actuators that open specially designed vents strategically positioned in the building. These vents serve two important purposes: high-level openings release the rising hot smoke, while low-level inlets draw in cooler, fresh air.

This coordinated airflow creates a pressure difference that pushes thick, toxic smoke upward and out of the building, much like how a chimney helps channel smoke away from a fireplace.

Picture this as an orchestrated dance of air currents—the hot smoke naturally rises due to its buoyancy, and by introducing cool air at the bottom, the system maintains a steady flow that prevents smoke from settling in stairwells or corridors where people need to escape. Without these carefully controlled vents, smoke would spread laterally and eventually descend, filling spaces with poisonous gases and obscuring visibility. This not only endangers lives but complicates firefighting efforts.

While this principle holds across all smoke ventilation systems, the way they execute it varies significantly depending on whether they rely on natural forces or mechanical assistance.

Natural smoke ventilation systems exploit airflow by using automatic or manual vents integrated into the building’s façade or roof. These openings take advantage of wind pressure and temperature differences to encourage smoke to rise and exit without powered devices. This method works well in buildings with sufficient height and design features that promote natural airflow. However, when architectural constraints limit airflow or speed is critical, mechanical smoke ventilation steps in.

Mechanical systems employ powerful fans, dampers, and smoke shafts to actively push smoke out, ensuring rapid clearance even when natural airflow is insufficient. These fans can move anywhere from 1,000 up to 20,000 cubic metres of air per hour depending on building size and risk factors. The system also maintains a pressure differential—usually between 50 and 100 Pascals—to prevent smoke from seeping into protected escape routes like staircases and corridors.

Integration is another key feature: these systems connect directly with fire alarms so activation happens automatically within about 60 seconds of detecting smoke. This timing is essential for keeping escape routes clear before conditions deteriorate. Additionally, ductwork is constructed to withstand extreme temperatures—up to 600°C for at least 30 minutes—to maintain functionality during the most critical moments.

Designing and installing these systems requires adherence to strict standards such as EN12101 and BS7346-8, ensuring they perform reliably when called upon.

From a safety perspective, successful operation hinges on coordinating multiple elements: sensor input, actuator response, vent positioning, fan capacity, and continuous maintenance. It’s this integration that transforms a collection of components into a life-saving mechanism that preserves both occupant safety and structural integrity in emergencies.

“Smoke ventilation systems don’t just clear toxic air; they create time—a precious commodity that can mean the difference between safe evacuation and tragedy.”

For building managers or developers considering installation, consulting with specialists like those at Mercor Fire Protection UK Ltd ensures your system matches specific site requirements—from natural solutions in well-ventilated structures to powerful mechanical units in complex designs—backed by nearly four decades of expertise tailored for UK regulations.

Having explored how these systems work fundamentally, it is now important to understand how different modes of operation—automatic versus manual—impact their effectiveness in real-world scenarios.

Automatic smoke ventilation systems stand out for their responsiveness and precision. When smoke is detected by sensors—whether through heat or particulate measurement—the system instantly triggers vents, dampers, or roof openings without waiting for human intervention. This rapid activation is critical in high-risk environments like high-rise buildings or commercial complexes where every second counts during an emergency.

The integration with centralised control panels allows building managers to monitor multiple zones simultaneously, ensuring that smoke is efficiently expelled floor by floor to keep escape routes clear. A prime example is Mercor UK’s mcr PROLIGHT E 100/150, an Automatic Opening Vent (AOV) that responds swiftly as soon as smoke is sensed, maintaining safety with minimal effort from occupants.

This hands-free operation largely removes the risk of delayed responses due to human error or absence at the scene. However, it also means these systems require diligent upkeep — sensor calibration and quarterly testing are essential to guarantee they operate flawlessly when called upon. Their complexity and automation lead to higher installation costs, often ranging from $5,000 up to $20,000 depending on building size and sophistication, but the peace of mind they offer in densely occupied buildings makes them invaluable.

In contrast, manual smoke ventilation systems place control directly into human hands.

Manual systems rely on occupants or designated personnel to initiate smoke clearance by flipping a switch or pulling a lever. While this setup generally entails lower installation and maintenance costs — typically between $1,000 and $5,000 for installation — it also has inherent risks. If a fire breaks out when no one is present or if the person responsible overlooks activation, smoke can accumulate unchecked, reducing visibility and endangering lives.

Still, manual systems are practical in smaller buildings where continuous monitoring isn’t feasible or in spaces where budget constraints limit technological upgrades.

Despite their simplicity, manual controls demand clear signage and regular drills so occupants understand how and when to activate them under pressure. Maintenance here focuses more on inspecting mechanical parts and accessibility rather than sensor performance. And because they don’t consume energy unless triggered manually, they present energy savings over automated counterparts.

| Feature | Automatic Systems | Manual Systems |

|---|---|---|

| Activation | Smoke sensors trigger automatic response | Human-operated switches |

| Response Time | Within seconds of detection | Dependent on human presence and action |

| Coverage Area | Can cover multiple zones centrally | Usually limited to specific locations |

| Maintenance Needs | Regular sensor calibration & system tests | Mechanical inspections & functionality checks |

| Installation Cost | Higher ($5,000–$20,000+) | Lower ($1,000–$5,000) |

| Reliability | High, but potential for false alarms | Varies depending on occupant vigilance |

| Energy Consumption | Continuous power required for sensors/control | Minimal – only when manually activated |

| Typical Use Cases | High-rise buildings, hospitals, commercial spaces | Small buildings, warehouses |

Selecting between automatic and manual systems means weighing factors such as building size, occupancy level, regulatory requirements, and budget constraints.

Both types play crucial roles in fire safety strategy; however, today’s best practice—especially in modern construction—is leaning toward automated options supported by reliable control panels and sensor technology. Integrating these systems with alarms and sprinklers creates a cohesive shield against fire hazards by not only evacuating smoke but also helping firefighters gain safer access to affected areas.

Companies like Mercor Fire Protection UK provide expertly-engineered solutions stocked locally to meet tight project timelines while adhering strictly to British standards like BS7346-8 and harmonised EN12101 regulations.

Whichever system you implement, remember that regular testing, maintenance, and staff training are non-negotiable pillars of effectiveness. This ensures your smoke ventilation system will perform its life-saving function precisely when it matters most.

Understanding the operational nuances sets the stage for a deeper examination of the system’s essential parts and design elements that bring smoke ventilation to life under pressure. These components work together to deliver optimal safety outcomes in complex building environments.

At the heart of every smoke ventilation system lies a coordinated set of components designed to work seamlessly during an emergency. Each part plays a specific role to ensure that smoke is extracted efficiently while maintaining safe escape routes. For instance, smoke vents are carefully positioned openings—often on roofs or high points of stairwells—that physically allow smoke to exit the building. Their location is no accident; engineers place them where natural buoyancy will help hot smoke rise out rapidly.

Alongside these vents, control panels act as the central nervous system. These panels receive signals from smoke detectors, then instruct actuators to open vents and dampers automatically, typically within seconds of detecting smoke. Modern control units not only ensure prompt response but also integrate with building-wide fire alarm systems, allowing coordinated evacuation efforts. This automation crucially reduces delays that manual opening methods may cause.

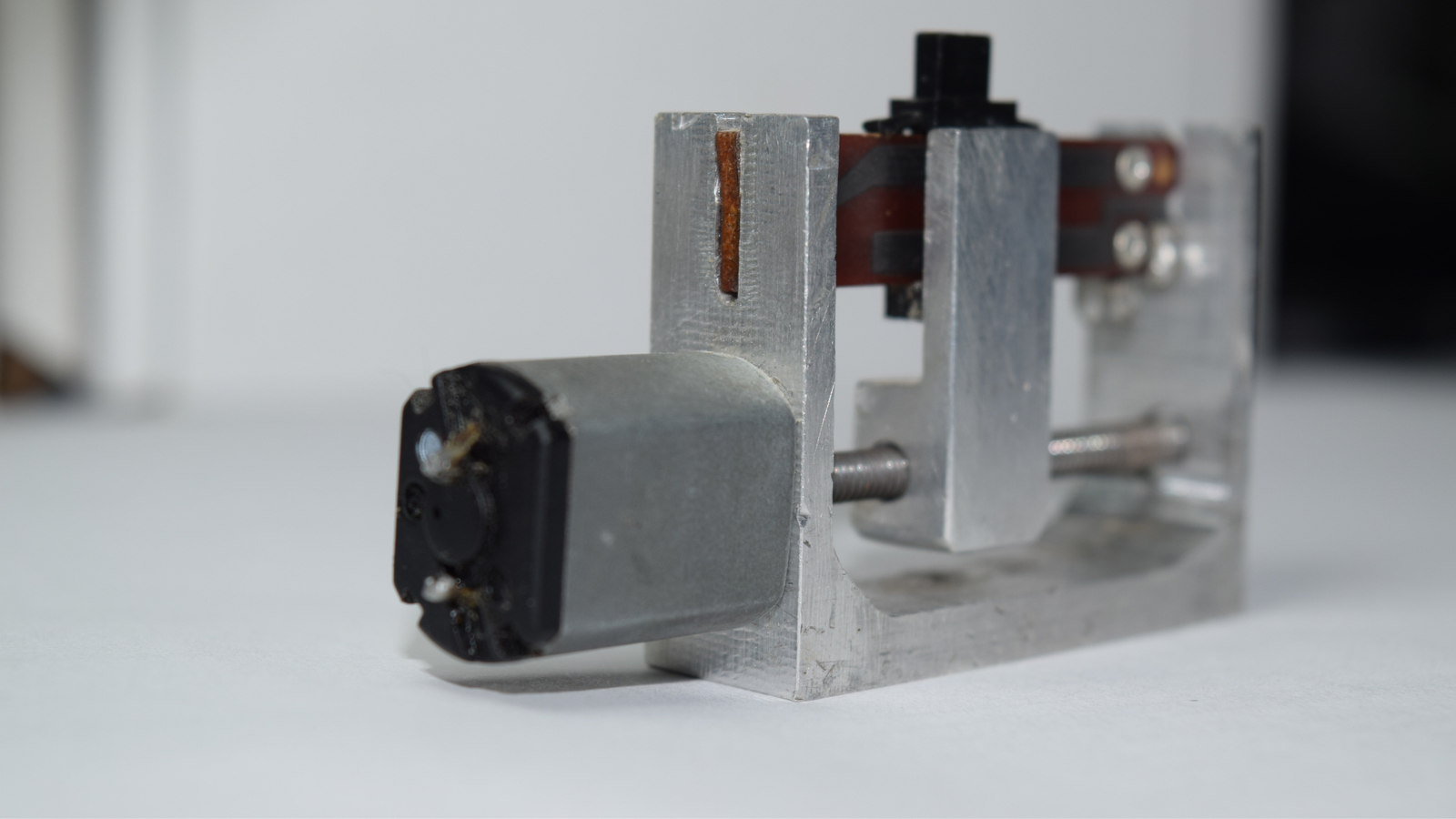

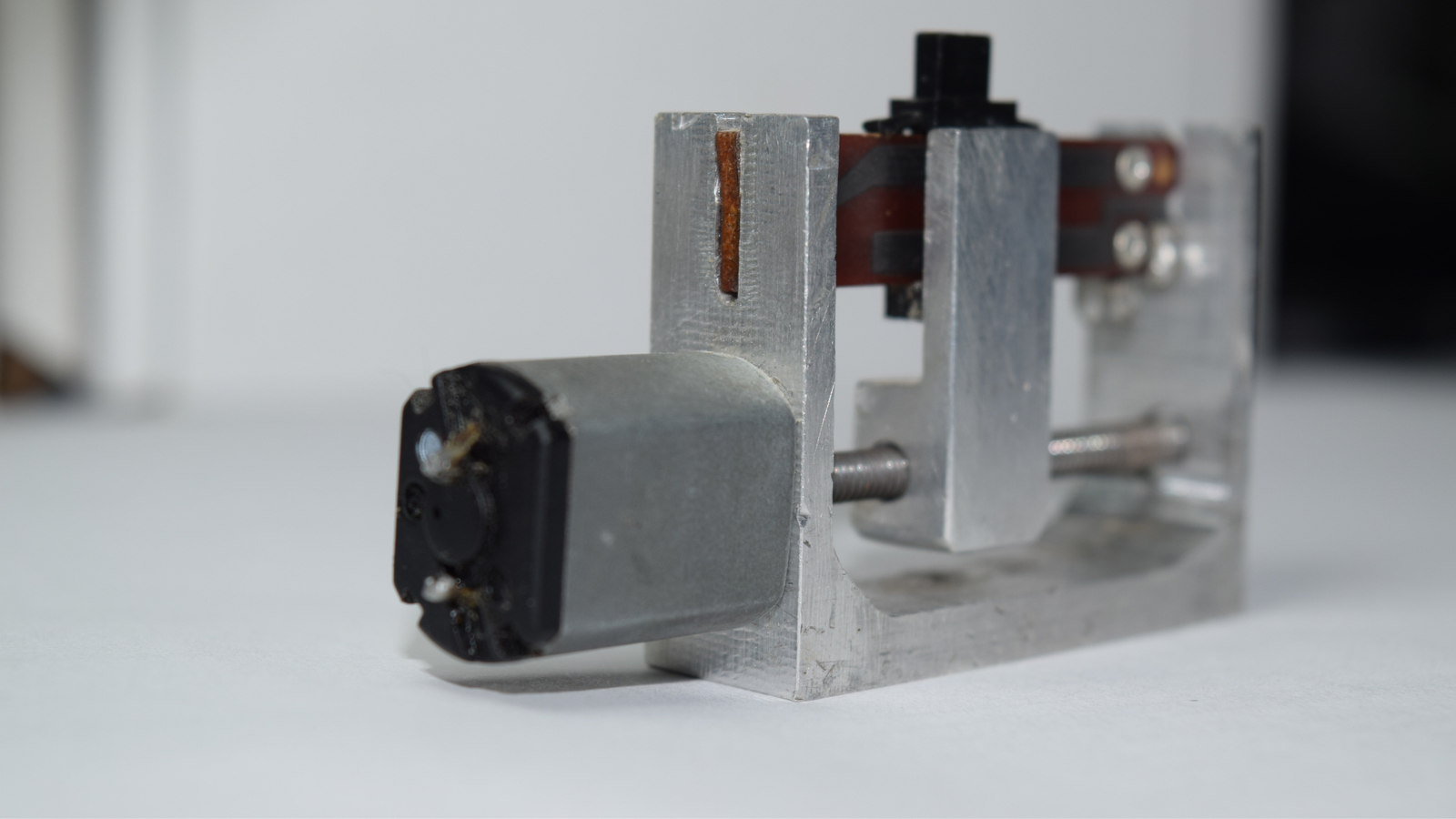

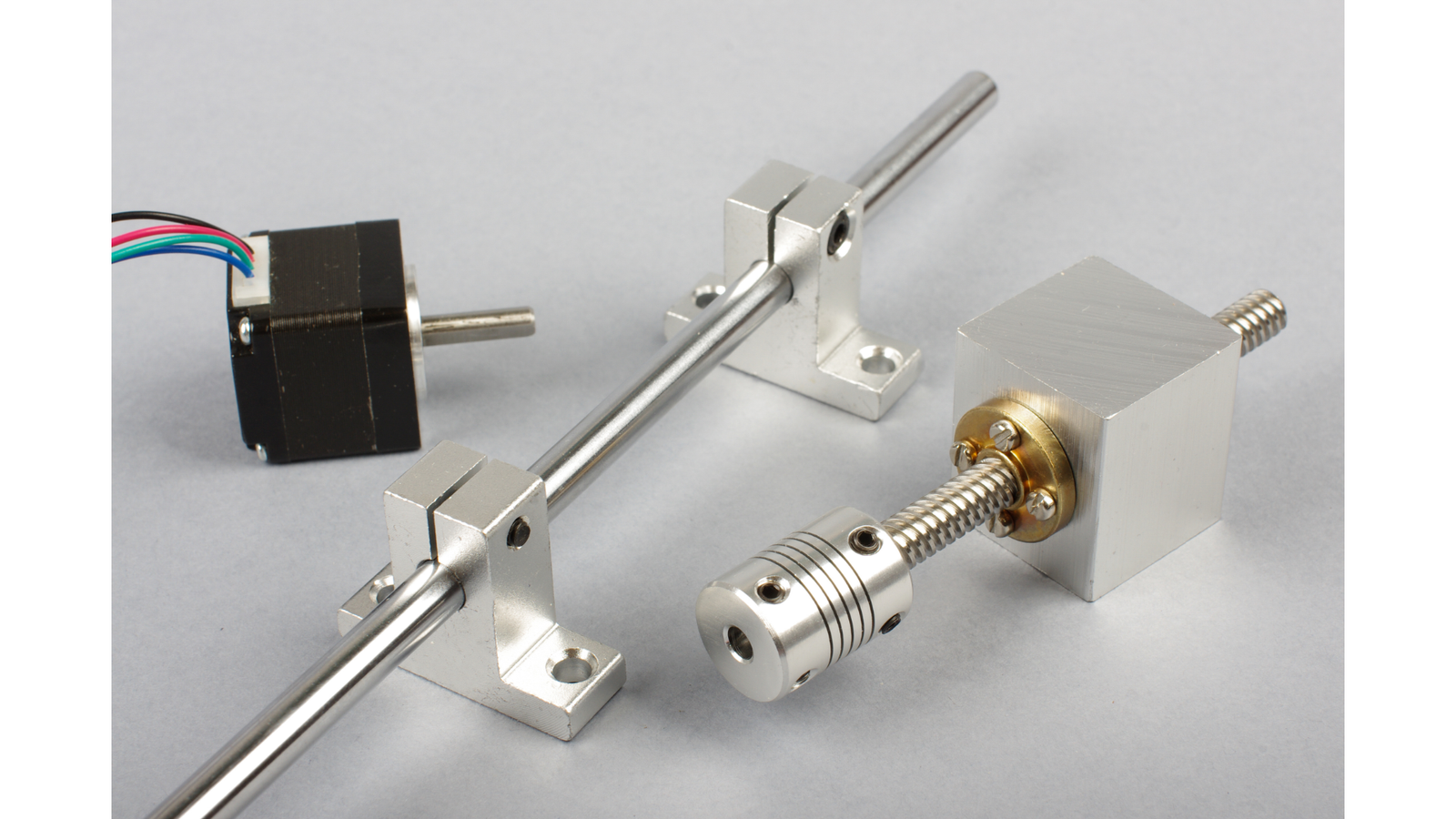

Speaking of actuators, these devices perform the essential task of physically moving vent covers and dampers into position. They must be fast, reliable, and corrosion-resistant since they often operate in outdoor environments exposed to weather. The actuator’s responsiveness directly affects how quickly smoke can be removed — slow movement could mean a dangerous buildup inside.

Meanwhile, smoke detectors serve as vigilant eyes, constantly monitoring air quality within critical escape routes. Their design specifications demand rapid response times—usually under 30 seconds—to minimise any lag before activation. Placing detectors strategically in corridors and lobbies ensures early detection of fires on a floor-by-floor basis.

Complementing smoke extraction is the often overlooked role of fresh air inlets. These controlled openings introduce cooler air into the protected areas below the smoke layer. The influx of fresh air helps push rising hot smoke upwards and out through vents more effectively, preserving clearer evacuation paths for occupants.

To achieve compliance with safety standards like EN 12101 and BS7346-8, designers consider airflow rates carefully. Adequate vent sizing—typically covering at least 5% of the floor area—is essential so smoke is cleared rapidly without creating uncomfortable drafts or excessive noise.

| Component | Typical Specifications and Notes |

|---|---|

| Smoke Vents | Operate automatically at temperatures between 68°C-90°C; sized to cover 5%+ floor area for effective extraction |

| Control Panels | Compliant with EN12101-10 standards; integrate with fire alarms |

| Actuators | Durable for outdoor use; operate within seconds |

| Smoke Detectors | Response time under 30 seconds; positioned throughout escape routes |

| Fresh Air Inlets | Balanced to maintain airflow pressure; designed to prevent backflow |

It’s worth noting that local warehouse stock availability—like Mercor Fire Protection UK Ltd‘s offerings—ensures quick deployment for new builds or retrofits without compromising on critical safety components. With nearly four decades of global expertise embedded in their solutions, such manufacturers help meet stringent regulations while supporting fast construction timelines.

Understanding these components individually proves vital, but their true effectiveness shines when meticulously integrated into a comprehensive system engineered specifically for a building’s unique architecture and operational needs. This integration forms the cornerstone for aligning with evolving regulatory frameworks and safety demands.

Compliance with fire safety regulations isn’t just a bureaucratic hurdle—it’s essential for safeguarding lives and property. In the UK, smoke ventilation systems must adhere to stringent standards set out in BS EN 12101, which governs smoke and heat control systems, including smoke vents. This standard ensures that when a fire breaks out, the system can swiftly and reliably clear smoke and toxic gases, maintaining visibility and breathable air for occupants while supporting firefighting efforts.

But meeting these standards goes beyond simply choosing compliant products. Every installation must be meticulously planned and executed to guarantee the system performs exactly as intended during emergencies. Property owners and managers need to understand that the installation phase demands professional expertise to ensure components such as vents, sensors, and control panels integrate seamlessly according to regulatory guidelines.

A poorly installed system can fail at critical moments—something no one wants to experience.

Furthermore, compliance requires more than just initial installation. Regular inspections and maintenance are mandatory under the regulatory framework, particularly driven by the Regulatory Reform (Fire Safety) Order 2005 that places responsibility on ‘responsible persons’ like property managers. This legal obligation is designed to prevent neglect from turning fire safety measures into ticking time bombs.

Maintenance routines should include visual checks for damage or blockages, functional testing of manual or automatic vent operations, cleaning of debris, lubrication of moving parts, and verification of electrical controls.

Establishing a maintenance schedule aligned with manufacturer instructions and British Standards Institute (BSI) recommendations is not a luxury but a necessity.

For instance, annual inspections by qualified technicians can help detect early signs of corrosion or mechanical wear before they escalate into system failures. Keeping detailed records of inspections and repairs also demonstrates due diligence in case of audits or insurance reviews.

Alongside system maintenance, staying informed about evolving regulations is crucial. Fire safety standards and guidelines can change as technology improves or new hazards emerge.

A proactive approach ensures your smoke ventilation system remains compliant over its entire service life rather than becoming obsolete or legally non-compliant.

Integrating compliance into every stage—from design to installation and ongoing upkeep—translates into a smoke ventilation system that truly protects people and assets when it matters most.

Achieving this level of reliability requires expert attention not only during initial setup but throughout the lifetime of the system. Next, we explore how professional installation combined with routine care keeps smoke ventilation functioning flawlessly day after day.

Proper installation is the foundation of a smoke ventilation system’s reliability. This isn’t a project for casual tinkering or DIY attempts; hiring certified professionals with expertise in fire protection systems is an absolute must. These specialists know exactly how to position and configure components like automatic opening vents, lobby dampers, and control panels to interact seamlessly with a building’s architecture and comply with regulations such as BS7346-8 and NFPA 92.

Misplaced vents or faulty actuator setups can compromise smoke clearance, effectively turning what should be a lifesaving system into an ineffective facade.

Additionally, precise installation involves careful integration of sensors and the control interface—elements that enable rapid detection and response to smoke presence. With modern smoke ventilation systems incorporating intelligent controls, any mistake in wiring or sensor calibration can delay activation or cause false alarms, both undesirable outcomes in urgent fire scenarios.

The intricacy of these interconnected parts means professional installation safeguards not just compliance but also peace of mind.

Beyond installation, routine maintenance plays a pivotal role in ensuring long-term functionality and safety.

Smoke ventilation systems face diverse challenges during their operational life—dust accumulation can block vents, actuators may lose responsiveness, motors can wear out, and power supplies might falter unexpectedly. Without scheduled maintenance, these small issues quietly escalate until the system fails when it’s needed most.

Industry best practise includes quarterly visual inspections and functional tests alongside a comprehensive annual maintenance session. During these checks, professionals clean smoke vents of soot and particulates, verify actuator operations by simulating emergency activations, test control panel responses, and confirm uninterrupted power supplies.

Regular maintenance also extends the lifespan of components significantly. Studies show that well-maintained smoke ventilation systems enjoy up to 30% longer operational lives—translating to thousands of pounds saved on premature replacements or extensive repairs.

On the other hand, neglecting upkeep turns minor malfunctions like blocked louvres or weak actuator springs into critical failures under fire conditions—risks no building manager should accept.

A property manager from Manchester once reported how their commitment to regular servicing paid dividends:

“After we implemented scheduled maintenance through Mercor Fire Protection UK Ltd., our system worked perfectly during an unannounced fire drill. It reassured us that occupants would have clear escape paths if anything serious happened.”

To make this manageable, setting reminders for maintenance dates and partnering with trusted suppliers like Mercor Fire Protection UK Ltd offers streamlined support. Mercor stocks key components—including lobby dampers and automatic opening vents—ready for prompt delivery across the UK within days. Their technical team provides expert advice to tailor service programmes ensuring smooth operation year-round.

The combination of expert installation and rigorous upkeep transforms smoke ventilation from simple equipment into essential infrastructure that protects lives and property.

Moving forward, it’s crucial to understand how these systems directly enhance safety measures and aid effective evacuation during emergencies.

Smoke ventilation systems play a pivotal role in fire safety by ensuring escape routes remain clear of smoke, enabling occupants to evacuate swiftly and safely. Imagine the terror of thick, choking smoke filling corridors and stairwells—the very paths meant for escape—reducing visibility to nearly zero and making breathing difficult. These systems combat that nightmare by quickly removing smoke, preventing it from accumulating and spreading through vital exit routes.

The result? Clearer air and better visibility, which directly improves the odds of safe evacuation.

The effectiveness of these systems extends beyond protecting occupants; they significantly aid firefighting efforts as well. Firefighters rely heavily on visibility to locate trapped individuals, assess the severity of the blaze, and apply extinguishing measures precisely. When smoke is actively extracted through strategic vents controlled by automated systems, firefighters can navigate buildings more confidently and respond swiftly without delays or hazards caused by thick smoke layers.

To put this into perspective, UK fire statistics show that buildings equipped with approved smoke ventilation systems experience approximately 30% fewer casualties during fire events compared to those without such protection. This striking figure underscores just how much difference an effective smoke control system makes—not just in theory but in real lives saved.

A core way these systems achieve such outcomes is through creating what experts call a smoke-free layer. By opening automatic vents at higher levels for exhaust and introducing fresh air from lower inlets, the system generates an upward airflow that pushes hot smoke away from lower escape routes.

This layered approach maintains safer temperatures—usually below 60°C (140°F)—inside escape corridors, drastically increasing survivability compared to conditions where heat and toxic gases build unchecked.

Furthermore, these systems reduce toxic gas exposure by up to 60%, lowering risks not only of immediate harm but also long-term respiratory problems for occupants who might otherwise inhale dangerous fumes during evacuation or post-fire cleanup. This highlights the critical health benefits alongside enhancing physical safety.

Recognising these extensive safety contributions helps clarify why investing in quality smoke ventilation components—like those offered by Mercor UK—and adhering to proper maintenance protocols is a non-negotiable aspect of modern building design and management.

“Smoke ventilation doesn’t merely delay disaster—it transforms potential tragedy into manageable risk.”

For detailed product information, technical support, or system specifications tailored to your building’s needs, visit Mercor UK. Their comprehensive solutions and expert assistance are invaluable resources on your path toward enhanced fire safety performance.

Understanding these key benefits highlights the critical role smoke ventilation systems play in safeguarding lives and property. To ensure unbeatable fire safety for your next project, request a quote today at https://mercor-uk.co.uk/request-a-quote/.

Keeping a smoke ventilation system in tip-top shape means regular inspections, testing those fans and vents, and clearing any debris or blockages. Think of it like a respiratory check-up for your building—neglecting maintenance can reduce system efficiency by up to 40%, putting lives at risk during a fire. So, schedule professional checks at least twice a year and never skip the quick monthly visual inspections to breathe easy!

Smoke ventilation systems are typically installed in high-risk areas like stairwells, corridors, atriums, and parking garages—basically the spots where smoke loves to party and block escape routes. These systems ensure smoke is quickly expelled, maintaining clear evacuation paths; for instance, buildings with proper smoke ventilation see a 30% improvement in safe evacuation times. So, if you want everyone out alive and kicking, those strategic airflow defenders are a must-have!

A smoke ventilation system is absolutely crucial for building safety compliance—think of it as the lungs of your building during a fire, clearing toxic smoke and giving occupants a fighting chance to escape. Studies show that effective smoke ventilation can reduce smoke temperatures by up to 30%, significantly improving visibility and reducing inhalation hazards. Without it, buildings risk non-compliance with fire safety codes and, more importantly, endanger lives. So yes, it’s not just important; it’s a life-saving must-have!

A smoke ventilation system kicks into action during a fire by automatically detecting smoke and heat, then venting it out through strategically placed openings like windows or vents—basically, it’s the building’s way of taking a smoky deep breath so people inside can see and breathe a little easier. By clearing toxic smoke, these systems reduce fire-related fatalities by up to 50%, giving occupants vital extra minutes to escape while also helping firefighters tackle the blaze more effectively.

Smoke ventilation systems come in three main flavours: natural, mechanical, and hybrid. Natural systems cleverly use windows and vents to let smoke escape without any fans, making them energy-efficient but dependent on weather conditions. Mechanical systems rely on fans and ductwork to actively suck out smoke, ensuring consistent performance but at a higher energy cost—studies show they can clear smoke 50% faster than passive setups. The hybrid system blends the best of both worlds, activating fans only when needed, balancing efficiency with reliability. Each type suits different building designs and safety needs, proving that when it comes to smoke ventilation, one size definitely does not fit all!

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Choosing the right actuator for your fire protection systems may seem straightforward at first just pick a size and type

UK mainland delivery

Stock on hand in our UK warehouse

Online and phone support

Safe online payment options