What Is an Actuator? Definition, Types, and Applications Explained

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Smoke ventilation systems might not be something you think about every day, but when a fire breaks out, they become one of the most important safety features in a building. Without proper smoke control, toxic gases and thick smoke can make escaping nearly impossible and put lives at serious risk. Whether it’s a simple vent relying on natural airflow or a powerful fan-driven system working behind the scenes, these setups are carefully designed to manage smoke and keep people safe. In this guide, we’ll break down the different types of smoke ventilation systems, how they work, and what factors matter most when choosing the right one for your building.

The main types of smoke ventilation systems include natural ventilation, which relies on the buoyancy of smoke and strategically placed vents or windows; mechanical ventilation, using fans and ducts activated by smoke detectors to extract smoke; and combined systems that integrate both natural and mechanical solutions. Each system type is selected based on building size, occupancy, and specific fire safety requirements to ensure effective smoke control and occupant safety.

Smoke ventilation systems play a crucial role in fire safety by managing smoke movement during a fire, which directly protects lives and property. When a fire breaks out, smoke and hot gases quickly fill enclosed spaces, reducing visibility and increasing the risk of smoke inhalation—one of the leading causes of death in fires.

Smoke ventilation systems are designed to control or remove this smoke, creating safer escape routes for occupants and easier access for firefighters.

There are two primary categories: natural and mechanical smoke ventilation systems.

Natural systems depend on the physical principles of heat and airflow. They use openings such as roof vents, windows, or shafts to allow smoke to rise naturally due to its lower density compared to fresh air. This process takes advantage of what engineers call thermal buoyancy—the tendency for hot air and smoke to rise above cooler air.

Natural ventilation is often simpler, cost-effective, and requires less maintenance but works best in smaller or less complex buildings where airflow paths can be carefully managed.

In contrast, mechanical systems incorporate fans, ductwork, and control panels that actively suck smoke from affected areas. These systems are essential in larger structures like hospitals, hotels, or high-rises where relying only on natural forces can be unreliable or insufficient.

Mechanical smoke extraction can maintain controlled airflows even in adverse weather conditions or complex building layouts. They often work automatically when detectors identify smoke, rapidly extracting harmful gases while maintaining pressure zones that block smoke from escaping into stairwells or corridors.

The impetus for modern smoke ventilation systems arose from tragic events such as The Our Lady of the Angels School fire in Chicago in 1958, where inadequate smoke control contributed to significant loss of life.

Following this tragedy and others like it, building safety codes around the world began mandating rigorous smoke management practises that incorporated both natural and mechanical solutions depending on building type and occupancy.

Today’s systems may also combine natural with mechanical elements in hybrid designs that optimise energy efficiency while ensuring rapid response to fires.

For instance, a building might use operable roof vents supplemented by fans that kick in when needed. Fire-rated dampers and barriers integrate with these systems to compartmentalise smoke spread within a building—keeping escape routes clear without compromising fire resistance.

| Type | Method | Best For | Advantages | Limitations |

|---|---|---|---|---|

| Natural | Openings & Vents | Low-rise buildings | Energy-efficient, low maintenance | Weather-dependent |

| Mechanical | Fans & Ducts | High-rises, complex layouts | Reliable under all conditions | Higher installation/operating costs |

| Hybrid | Combination | Varied building requirements | Balances energy & performance | More complex design required |

Selecting the right system depends on factors including building size, occupancy level, climate conditions, and regulatory compliance requirements.

It’s critical these systems are carefully designed by specialists who understand local codes and unique architectural challenges.

Building on this framework, we will next examine the distinct attributes and practical considerations between natural and mechanical ventilation approaches—helping you make informed decisions tailored specifically to your property’s needs.

Natural ventilation systems work by harnessing the simple, ever-present forces of nature—wind currents and the buoyancy of hot smoke—to clear smoke from a building during a fire. These systems often rely on automatic opening vents (AOVs) or windows that open when smoke is detected, allowing smoke to rise and escape naturally. The design simplicity here is a major strength. Fewer moving parts mean there’s less that can go wrong, which translates to lower installation and maintenance costs—an appealing feature for smaller buildings or those with straightforward layouts.

Plus, because they don’t draw electricity to operate fans or motors, natural systems are eco-friendly by default, helping reduce energy consumption and supporting sustainability goals.

Yet despite these clear advantages, natural ventilation isn’t always a perfect fit.

Natural systems depend heavily on external environmental conditions like wind speed and direction. On calm days or in buildings tucked away from prevailing winds, the system’s effectiveness can wane, leaving smoke lingering longer than desirable.

Additionally, natural ventilation struggles to handle complex building geometries or tall structures where natural airflow patterns become unpredictable. For these reasons, natural ventilation suits applications such as low-rise buildings, warehouses, or atriums with large openings where fresh air easily circulates.

When natural forces aren’t enough, mechanical ventilation steps in with precision and power.

Mechanical ventilation employs fans, ducts, and automated controls designed to extract smoke swiftly and reliably regardless of outside weather conditions. Sensors detect smoke early and trigger fans that channel it out through vent shafts or rooftops.

This ability to deliver consistent performance makes mechanical systems especially important in high-rise buildings, underground parking garages, or other complex layouts where uncontrolled smoke movement could threaten occupant safety and hinder firefighting efforts.

Beyond just moving air efficiently, mechanical systems offer refined control over how smoke behaves inside a building.

Because these systems actively push or pull airflows, they allow engineers to compartmentalise fire zones more effectively. That means controlling where smoke goes—keeping escape routes clearer and protecting unaffected areas longer.

While mechanical systems require higher upfront investment and ongoing maintenance—including quarterly or biannual checks—their unmatched efficiency at evacuating larger volumes of smoke quickly often justifies the cost.

| Feature | Natural Ventilation Systems | Mechanical Ventilation Systems |

|---|---|---|

| Cost | Cost-effective with fewer components needing upkeep | Higher initial investment and maintenance |

| Integration | Simple integration into architectural designs | Requires more complex installation |

| Environmental Impact | Environmentally friendly due to zero energy use | Consumes electricity during operation |

| Smoke Removal Rate (ACM) | 0.5 to 1.0 air changes per minute | 1.5 to 3.0 air changes per minute (up to triple) |

| Suitability | Best for low-rise buildings and open spaces | Ideal for high-rise buildings and complex layouts |

| Control Over Smoke Flow | Limited | Superior control over internal smoke flow |

From an operational perspective: natural ventilation may achieve between 0.5 to 1.0 air changes per minute (ACM), while mechanical ventilation can push this rate up to 3.0 ACM—tripling the pace of smoke removal. This difference is crucial when every second counts during an evacuation.

Ultimately, selecting between these two types must consider factors like building size, occupancy levels, local climate conditions, and budget constraints.

Real-world experience shows many modern developments benefit from a hybrid approach—incorporating elements of both natural and mechanical ventilation systems to optimise fire safety tailored precisely to their design challenges.

Whatever route you choose, adherence to regulatory standards like EN 12101-2 for natural systems or EN 12101-3 for mechanical ones ensures legal compliance and maximises occupant protection—a goal at the heart of all fire safety planning efforts.

Having established how different ventilation technologies operate within fire safety strategies, we turn next to understand the critical parts and design features that bring these systems to life in real-world settings.

When it comes to smoke ventilation systems, the components are like the organs in a living body — each plays a vital role in keeping the entire system functioning smoothly. At the heart of mechanical smoke control lie heavy-duty fans. These powerful devices move large volumes of smoky air out of a building quickly, creating clear escape routes for occupants and better visibility for firefighters. Without fans, many commercial and high-rise buildings would struggle to achieve the rapid smoke extraction necessary to save lives.

Of course, simply moving smoke is not enough. It needs well-planned pathways—the job of ducts. These channels transport smoke from hazard areas to safe exhaust points like roof vents. The ducts must be constructed from fire-resistant materials rated to withstand intense heat—usually for at least 60 minutes—so they don’t fail and allow smoke to travel to unintended areas.

Dampers, often overlooked but extremely important, regulate airflow inside these duct networks. In a fire event, certain dampers automatically close or open to control the movement of smoke and maintain compartmentation. Imagine them as smart gates that direct smoke flow accurately—preventing it from spilling into protected zones while ensuring extraction paths stay clear.

On the building exterior or roof, you’ll find vents and Automatic Opening Vents (AOVs) that act as exit points for smoke, activated either manually or automatically through control panels connected to smoke detectors. These components must be carefully selected based on the building’s size, use, and architectural demands. For example, Mercor UK’s mcr LAM Roof Louvre combines durability with an elegant design suited for efficient rooftop smoke discharge while complementing modern construction aesthetics.

Here’s a brief overview of key components:

| Component | Function | Typical Specification |

|---|---|---|

| Fans | Extract smoke rapidly | Airflow: 1,000 – 20,000 m³/h |

| Ducts | Convey smoke safely | Fire-resistance rating EI60+ |

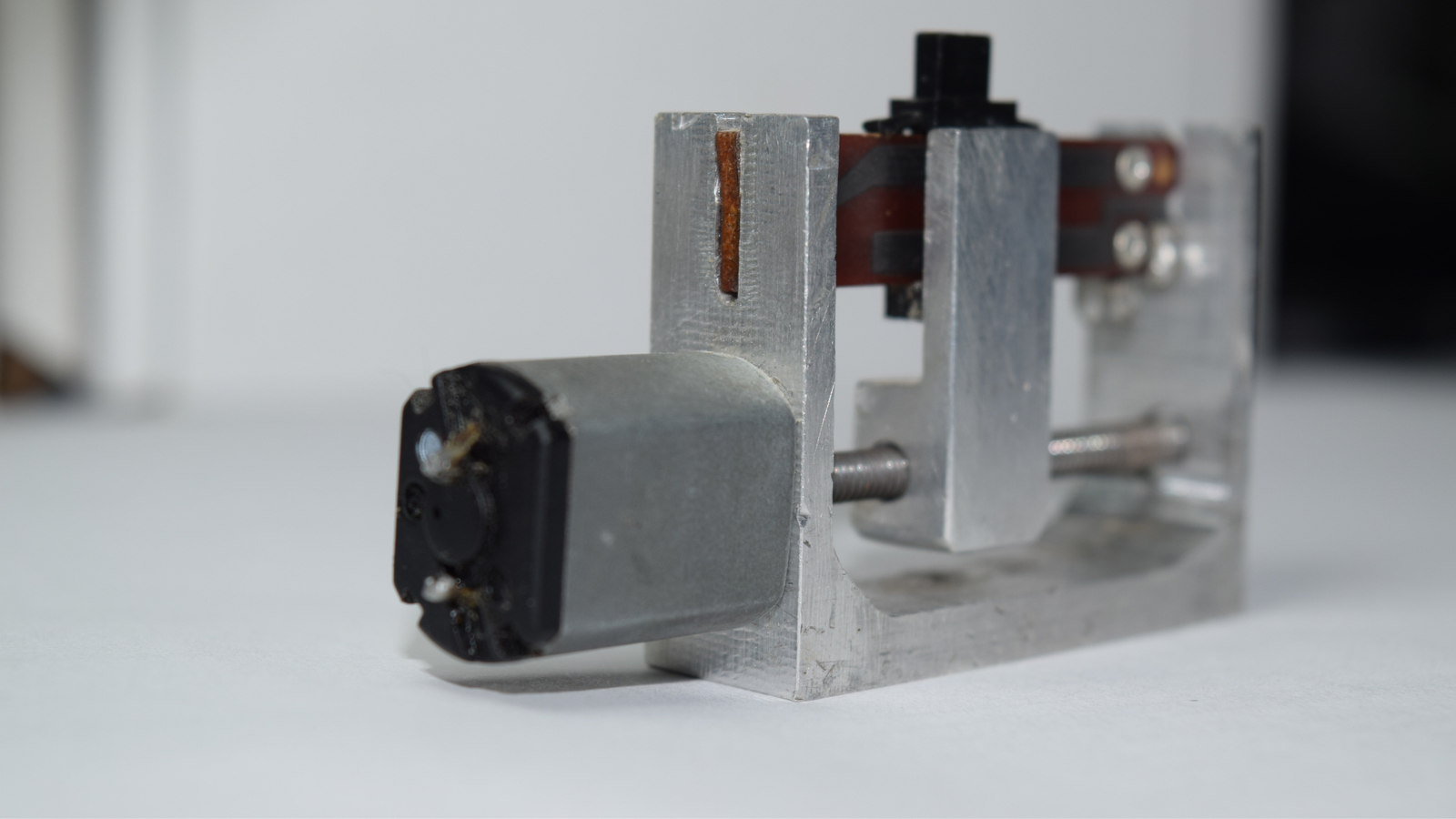

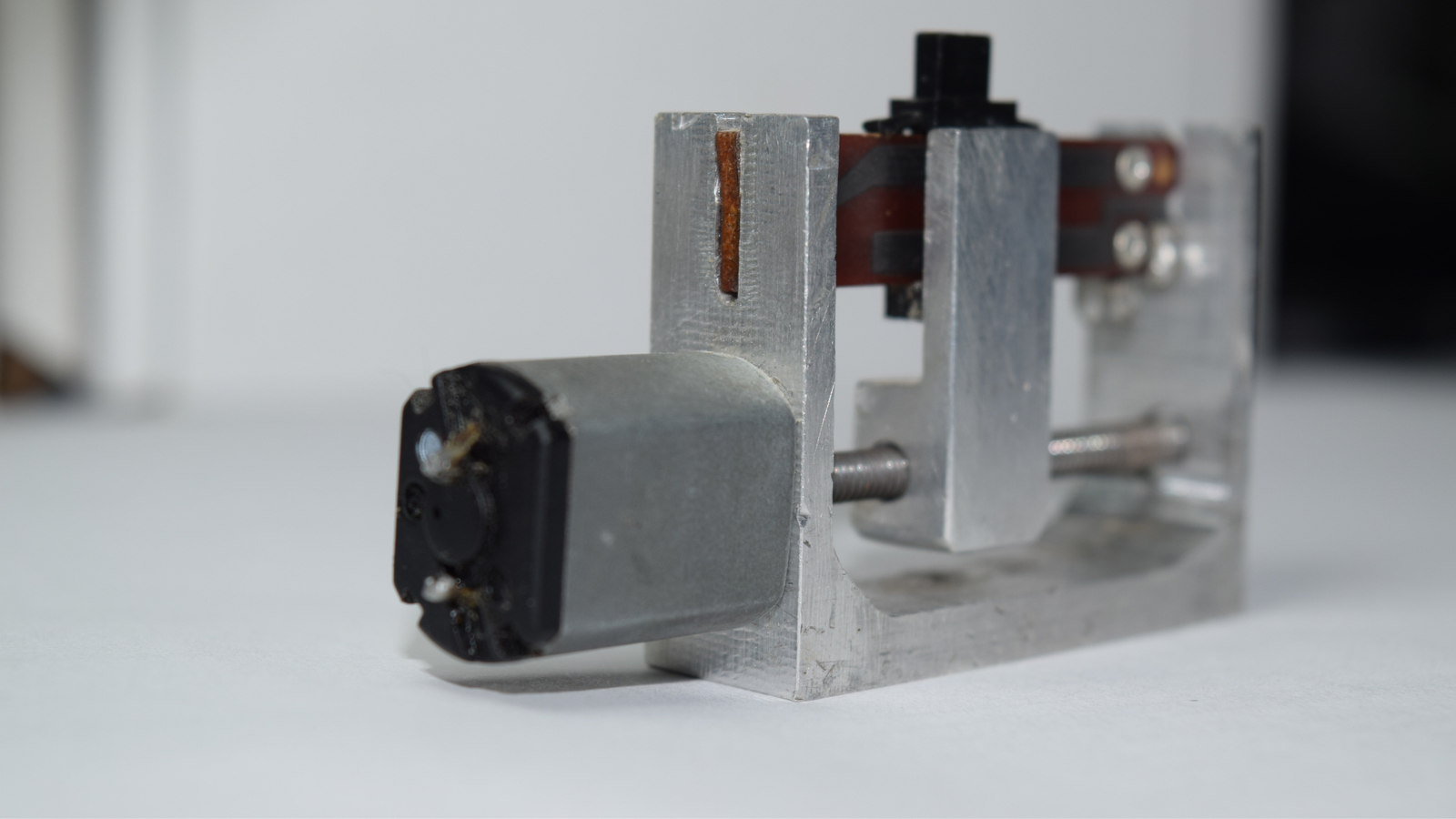

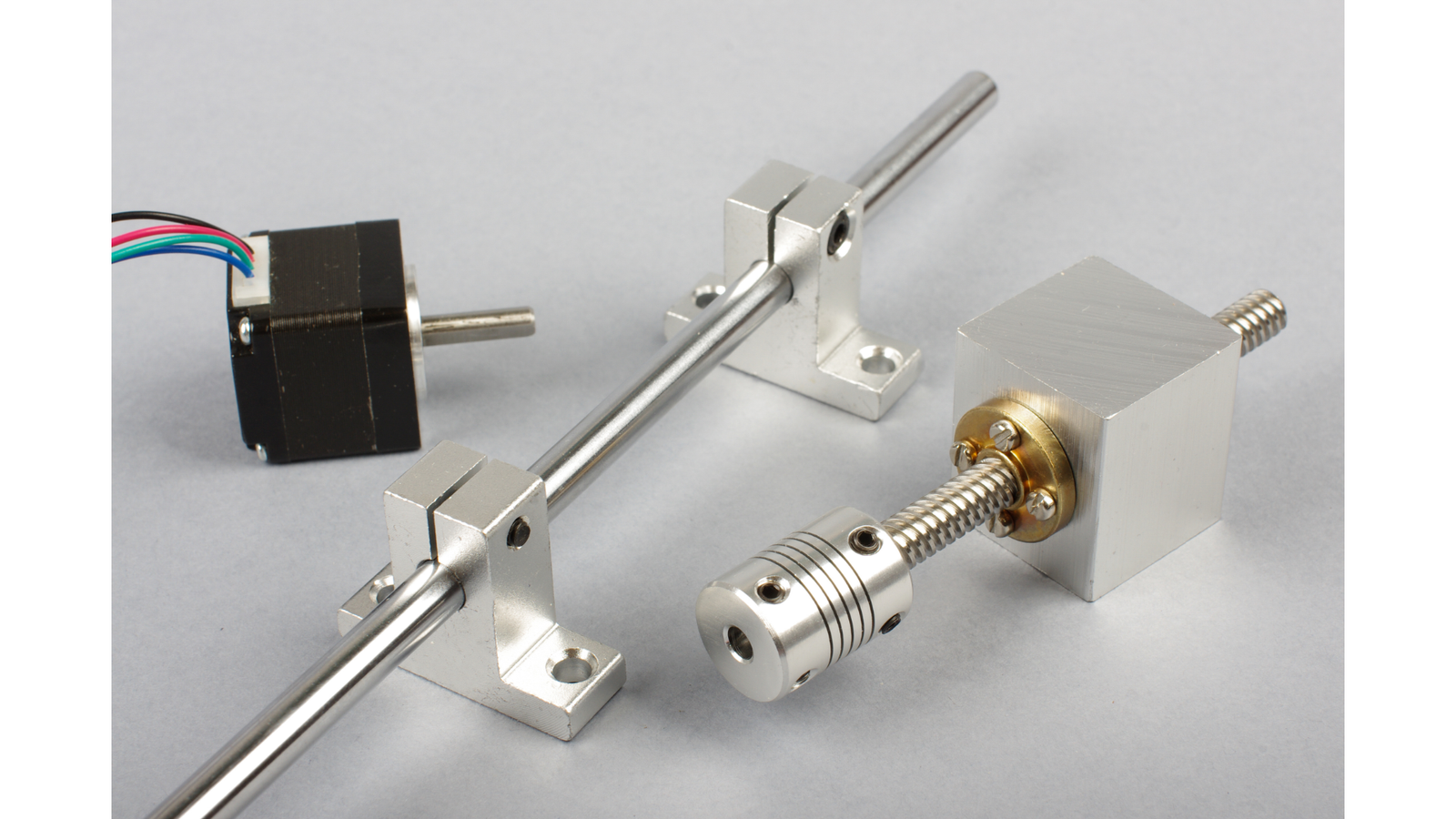

| Dampers | Control airflow direction | EN 12101-8 compliant actuators |

| Vents / AOVs | Smoke exit points | Free area ranging 0.5 – 1.5 m² |

| Control Panels | Manage activation timing & coordination | Must meet EN 12101-9 standard |

Beyond individual parts lies the design strategy—the architecture behind integrating these components into an effective system.

Proper placement of vents and dampers is one of the most important design considerations. Instead of randomly scattering components, designers analyse airflow patterns during fire conditions to position equipment where it maximises efficiency. Smart placement avoids dead zones where smoke could accumulate dangerously.

According to research reported by the UK Fire Protection Association, ventilation systems designed with strategically placed vents and dampers can boost evacuation success rates by up to 40%. That means more people get out safely when these systems are optimised—not just installed.

Automation has further revolutionised this field. Advanced control panels link with sensors and detectors to open vents precisely when smoke is detected and close unaffected areas automatically. This rapid response ensures fresh air supply and prevents unnecessary energy loss during normal operation.

Durability is another cornerstone of design. Fire safety equipment must withstand extreme temperatures, humidity fluctuations, and long periods without activation—yet perform flawlessly under emergency stress. Materials used are rigorously tested for longevity alongside easy maintenance access, since regular inspections keep systems reliable over their service life.

When selecting or upgrading your building’s smoke ventilation system, partnering with experienced providers like Mercor Fire Protection UK ensures you receive tailored solutions backed by decades of expertise—products designed specifically for compliance with UK regulations and tested for peak reliability under fire conditions.

Understanding these essential components and design priorities sets the stage for exploring how smoke ventilation integrates seamlessly within a building’s architecture to enhance overall safety and function.

Integrating a smoke ventilation system into the overall building design demands a blend of functional engineering and architectural foresight. It’s not simply about installing fans or vents; it’s about embedding these systems in ways that support both safety and aesthetics without compromising either.

A successful integration respects the flow of air, the structure’s shape, and the materials used, all while aligning with fire regulations. For example, natural smoke vents are often placed near roof ridges or upper facades—areas where smoke naturally rises—making use of the building’s form to facilitate effective evacuation of smoke.

Moreover, attention to architectural details like fire-rated barriers and compartmentation is essential to prevent smoke from spreading beyond intended zones. These barriers must fit precisely into walls and ceilings without gaps that could undermine the system’s effectiveness.

This requires close collaboration between fire engineers, architects, and HVAC specialists during design stages to ensure every damper, louvre, or vent aligns perfectly with structural elements. Neglecting this can result in costly retrofits and a potential increase in risk during emergencies.

When evaluating architectural integration, several elements come into play:

These factors become even more nuanced when comparing new constructions with retrofit projects.

In new builds, architects and engineers have the advantage of integrating smoke ventilation solutions from the ground up. This foresight allows for well-planned shafts, dedicated ductwork, and precisely positioned automatic opening vents (AOVs) aligned with both fire safety codes and building aesthetics.

The process can incorporate advanced features such as heat recovery units or demand-controlled ventilation to balance energy efficiency alongside emergency readiness. At Mercor UK, we emphasise this early-stage collaboration as it yields highly reliable systems that exceed regulatory standards.

Retrofitting existing buildings presents different challenges—walls may be solid concrete or brickwork limiting space for ductwork, structural constraints might complicate vent placement, and integration with existing HVAC systems risks unintended smoke circulation if not carefully managed.

Innovation is key: flexible duct systems, slim profile dampers like our mcr WIP LD series, and modular components allow adaptation without major reconstruction. While retrofits tend to be more complex and expensive, careful planning combined with products tailored for adaptability can deliver effective smoke control even in older structures.

Whether designing new builds or upgrading older ones, compliance with safety regulations such as EN 12101-2 for natural ventilation systems remains non-negotiable. This ensures legal adherence and confidence in system performance during emergencies. Coordination with building code officials early on facilitates smoother approvals and avoids costly redesigns.

Understanding how these systems fit architecturally paves the way toward meeting strict safety mandates that govern their use across various building types. Next, we examine how adherence to these regulations ensures both legal compliance and occupant safety within the complex framework of fire protection.

Adhering strictly to fire safety regulations isn’t just a bureaucratic box-ticking exercise; it’s the backbone that guarantees your smoke ventilation system will perform effectively when it really counts. In the UK, the framework is centred around Building Regulations Document B, which outlines comprehensive fire safety requirements tailored to protect lives and property. These regulations don’t merely suggest standards—they mandate precise criteria such as smoke control performance, material fire resistance, and ventilation system integration.

The crux of these rules is to ensure that smoke ventilation systems maintain clear escape routes by efficiently removing hazardous smoke during a fire, allowing occupants crucial time to evacuate and helping firefighters gain safer access. By complying with these standards, building owners reduce liability risks while enhancing occupant safety.

As an example, the materials used in ductwork and vents must be fire-resistant and tested to certified standards—failure to meet this can result in costly fines or shutdowns by local authorities.

Recent reports show that over 30% of commercial building fires escalate due to insufficient smoke control. This highlights why regulations like those set out in UK Building Regulations Document B are not optional but essential. Modern guidelines introduce mandatory performance-based approaches where systems must be tested under actual fire conditions, ensuring reliability rather than relying on theoretical designs alone.

For businesses operating commercial kitchens or industrial sites, adherence to updates such as the 2025 NFPA 96 standard is critical. This includes monthly hood cleanings and UL-300 compliant fire suppression systems which significantly reduce fire risk associated with grease buildup—a detail frequently overlooked until it becomes a hazard.

At Mercor UK, we understand these complexities firsthand. Our products go beyond simply meeting legal requirements; they’re engineered expressly to surpass them. This includes incorporating advanced smoke control technologies designed for versatile building environments, whether new projects or retrofits needing enhanced access panels or upgraded suppression systems.

This proactive approach results in lower long-term maintenance costs and smoother regulatory audits.

Recognising how deeply these regulations impact every aspect of fire safety shifts compliance from a mere obligation into a vital safeguard—strengthening protection for lives and property alike, while fostering operational resilience. Next, exploring the tangible benefits of effective smoke control will reveal why investing in these systems pays dividends far beyond compliance alone.

First and foremost, the primary goal of any smoke ventilation system is life protection. Smoke inhalation is a silent killer—it causes more than half of all fire-related fatalities. When a fire breaks out, toxic gases spread rapidly through a building, often faster and deadlier than the flames themselves.

An effective smoke ventilation system doesn’t just remove smoke; it actively creates safer, clearer escape routes by swiftly evacuating harmful particles from occupied areas. This immediate reduction in smoke density significantly reduces the risk of asphyxiation and helps occupants breathe cleaner air while evacuating.

Studies reveal that well-designed smoke control can increase safe evacuation time by 10 to 15 minutes on average. In an emergency, every additional second counts—these systems buy precious moments that allow more people to exit safely before conditions become life-threatening. This protective benefit fundamentally shifts the outcome of fire events from tragedy to survival.

Beyond protecting lives directly, controlling smoke has a profound effect on reducing property damage.

Smoke and soot are corrosive forces—they infiltrate surfaces, electronics, fabrics, and finishes with acidic compounds that cause accelerated deterioration. A prompt removal of smoke through adequate ventilation limits exposure time and minimises the accumulation of these damaging substances. When smoke lingers inside a building unchecked, it magnifies repair costs substantially.

For homeowners or facility managers, this translates into thousands saved in post-fire restoration expenses.

Additionally, early smoke evacuation preserves critical infrastructure elements such as wiring and HVAC systems which might otherwise require costly replacements due to soot contamination. In essence, investing in efficient smoke control is an investment in limiting cascading damage after the fire itself is extinguished.

While saving lives and limiting financial loss are vital outcomes, firefighter safety often goes underappreciated despite being equally impactful.

Firefighters enter hostile environments loaded with risks. Visibility is one of their greatest challenges—dense smoke hamstrings their ability to locate victims and assess hazards. Effective smoke ventilation clears air pathways and lowers ambient temperature levels inside burning structures, creating a safer environment for responders.

With improved visibility and cooler conditions, firefighters can act faster, making tactical decisions confidently without guesswork caused by obscured vision or heat exhaustion risks. This not only helps limit the fire’s spread but also reduces their exposure time inside dangerous zones, enhancing overall operational efficiency.

| Benefit Category | How Smoke Control Enhances It |

|---|---|

| Life Protection | Reduces inhalation risk via quick evacuation of toxic gases |

| Property Damage | Limits corrosive soot exposure on electronics & interiors |

| Firefighter Safety | Improves visibility & comfort for faster response |

To maximise these advantages, integrating high-quality smoke ventilation components like those from trusted suppliers—such as Mercor Fire Protection UK Ltd—is essential. Their products range from multi-blade dampers to intelligent roof vents and control panels, offering reliable performance tailored to complex building demands across the UK.

Recognising these critical benefits highlights why choosing the right type of smoke ventilation system is pivotal in safeguarding lives and property. Next, we explore how to make an informed decision that suits your building’s unique needs.

Choosing the right smoke ventilation system isn’t a one-size-fits-all decision. It hinges on a thoughtful balance of building size, occupancy, climate considerations, and of course, budget. When you picture a sprawling hospital or an office skyscraper, mechanical smoke ventilation often becomes essential. These systems can manage complex airflow paths in large, multi-level layouts, ensuring that smoke doesn’t overwhelm escape routes or firefighting operations.

Beyond just size, think about how many people are inside your building regularly. High occupant density demands a ventilation system that can quickly evacuate smoke to protect lives effectively. Mechanical systems equipped with high-capacity fans and sensors provide this reliability, especially during critical moments when seconds matter most. Conversely, smaller buildings or those with simpler floorplans might find natural ventilation systems both sufficient and cost-effective, relying on carefully designed vents and openings to harness smoke’s natural buoyancy.

Climate plays its silent but powerful role too. Natural ventilation depends heavily on external conditions like wind direction and temperature differences to drive airflow. In areas with harsh winters or hot summers, maintaining comfort while also ensuring rapid smoke extraction requires extra planning. Sometimes hybrid systems—melding natural airflow with mechanical assists—offer an elegant solution by adapting to changing weather without compromising safety.

That’s why consulting with experts such as Mercor UK proves invaluable. They bring deep industry knowledge combined with advanced product ranges—from the efficient mcr WIP LD dampers to automatic opening vents and precise control panels—to tailor a solution that fits your building’s unique challenges while meeting all relevant fire safety codes. Their expertise ensures not just compliance but operational peace of mind.

For bespoke advice and comprehensive support tailored exactly to your project’s needs, visit Mercor UK — where expert guidance meets cutting-edge fire protection technology.

Selecting the right smoke ventilation system is crucial for safeguarding occupants and property. To ensure optimal fire safety tailored to your building’s specific needs, request a quote today at Mercor UK.

Different smoke ventilation systems vary in effectiveness, but all aim to control smoke to save lives and property; natural ventilation can reduce smoke concentration by up to 60%, while mechanical systems often achieve over 80% efficiency in clearing smoke quickly. Combining both usually offers the best protection, as studies show buildings with hybrid systems see a 30% faster evacuation time and a significant drop in smoke-related injuries compared to those with no or single-method ventilation.

Smoke ventilation systems in buildings mainly fall into three categories: natural, mechanical, and hybrid. Natural systems use openings like windows and vents to let smoke escape—think of it as the building taking a smoky breath; mechanical systems employ fans and ducts to actively push smoke out, which is crucial in larger or complex structures where natural airflow just won’t cut it; and hybrids combine both methods for maximum efficiency. Studies show that well-designed mechanical systems can reduce smoke density by up to 60%, making escape routes safer during a fire.

Natural smoke ventilation systems rely on the simple genius of Mother Nature—using strategically placed vents and windows to let hot smoke escape, no electricity required. In contrast, mechanical systems are the tech-savvy firefighters, employing fans and ducts to actively pull smoke away, often ensuring a 30-50% faster clearance rate in enclosed spaces. While natural systems save on energy costs and maintenance, mechanical ones offer precision and reliability, especially in complex buildings where a breeze just won’t cut it.

Installation and maintenance of smoke ventilation systems vary by type—natural systems require precise architectural integration and regular spring-and-fall inspections to ensure vents open smoothly, while mechanical systems demand professional installation of fans and sensors, plus quarterly testing to prevent failures; neglecting upkeep can increase malfunction risk by up to 40%, compromising fire safety—so whether you’re relying on the whisper of a window or the roar of a fan, routine checks are non-negotiable for guaranteed performance when flames decide to RSVP.

Selecting a smoke ventilation system hinges on factors like building height, occupancy type, fire load, and architectural design—after all, you wouldn’t fit a spaceship’s smoke system into a cosy café! For instance, high-rise buildings often require pressurised stairwells and mechanical ventilation to combat stacked smoke layers, while warehouses might rely on natural ventilation due to their open layouts. Studies show that well-chosen systems can reduce smoke-related fatalities by up to 50%, proving that picking the right vent isn’t just hot air—it’s lifesaving science.

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Choosing the right actuator for your fire protection systems may seem straightforward at first just pick a size and type

UK mainland delivery

Stock on hand in our UK warehouse

Online and phone support

Safe online payment options