What Is an Actuator? Definition, Types, and Applications Explained

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Mechanical smoke ventilation systems might not be something you think about every day, but when a fire breaks out, they can make all the difference between safe escape and danger. These systems don’t just help get rid of smoke—they clear the way for people to leave quickly and safely. At Mercor Fire Protection UK, we understand how crucial it is to have reliable smoke ventilation, which is why we’ve put together this guide to explain how these systems work, what goes into designing them, and how to instal them properly. Whether you’re a building manager or just curious about fire safety, this article will give you a clear picture of what mechanical smoke ventilation really means for protecting lives and property.

Mechanical smoke ventilation systems use powered fans and dampers to efficiently extract smoke from buildings during a fire, helping to maintain safe evacuation routes and reduce smoke inhalation risks. At Mercor Fire Protection UK, we offer advanced mechanical smoke ventilation solutions—including smoke exhaust dampers, automatic opening vents (AOVs), and control panels—that comply with UK fire safety regulations to safeguard lives and property.

At their core, mechanical smoke ventilation systems serve one essential purpose: to remove smoke from a building during a fire event, ensuring that escape routes remain clear and that people can evacuate safely. Unlike natural ventilation methods, which rely on open windows or vents, these systems use powered fans and carefully designed ductwork to actively extract smoke regardless of external weather conditions. This capability becomes crucial in buildings where architectural complexity—such as high-rise offices or underground garages—makes natural smoke clearance unpredictable or ineffective.

The operation typically involves a network of motorised ventilators, including roof vents and lobby dampers, that open automatically upon detection of smoke through integrated sensors. These components work in concert with control panels that manage airflow patterns, preventing the spread of smoke between different zones while directing it out of the building efficiently. Such precision requires engineering tailored to the unique layout and function of each structure—a fact that underscores why off-the-shelf solutions rarely suffice when it comes to life safety systems.

To ensure optimal performance, system designers focus on calculating free area sizes—the clear passage available for air movement within dampers or vents—and matching these to anticipated smoke volumes. For example, at Mercor Fire Protection UK, products like the mcr WIP LD 1.0 GFA offer a generous 1.03m² free area, allowing them to handle significant smoke extraction without restricting airflow. Selecting the right size and type of damper or actuator in conjunction with effective control panels can make all the difference between a system that merely complies with regulations and one that genuinely enhances occupant safety.

Industry research supports this approach; data from the Building Research Establishment (BRE) shows that well-designed mechanical smoke ventilation systems can reduce fatalities by up to 50% during fire emergencies. This dramatic impact highlights not just the importance of installation but also ongoing maintenance and validation—a neglected system can fail precisely when it’s needed most.

Beyond life safety, these systems protect property by limiting the harmful effects of smoke on sensitive equipment and interiors. Smoke damage often causes more extensive repair costs than the fire itself, so robust ventilation also serves as sensible risk management. Moreover, clear visibility maintained by extracting smoke assists firefighters in locating hazards and victims faster, ultimately reducing response times and potential injuries.

In today’s climate where building standards grow ever more stringent and architectural designs more complex, mechanical smoke ventilation is increasingly viewed as an indispensable element rather than an optional feature. By leveraging advanced products, reliable controls, and expert consultation—services fully supported by companies like Mercor Fire Protection UK—building managers can create safer environments while meeting regulatory demands efficiently.

If you oversee building safety or specification projects, engaging early with trusted suppliers who stock certified products and offer technical support can streamline installation timelines and ensure compliance from day one. With UK-stocked items delivered within days and comprehensive advice available from Mercor’s Manchester team via phone or online, integrating mechanical smoke ventilation has never been more accessible or dependable.

Grasping how these systems function sets the stage for a closer look at the individual parts involved—their roles, interactions, and how they come together to keep occupants safe in critical moments.

Every mechanical smoke ventilation system is a carefully balanced orchestration of components, each designed to play a vital role in managing smoke during a fire. When you look at these systems, it’s not just about moving air; it’s about controlling smoke to preserve safe escape routes and reduce damage.

The core elements—smoke dampers, extract fans, and control panels—perform distinct but interconnected functions that ensure this safety.

Smoke dampers act as gatekeepers inside the ventilation ducts. Imagine them as fire doors hidden within your building’s airflow pathways. Their job is to close tightly when smoke is detected, effectively sealing off sections of ductwork to block smoke from spreading into safe areas like stairwells or adjacent rooms.

This containment is crucial because it prevents smoke from compromising evacuation routes or contaminating spaces that need to remain clear for occupants and first responders.

These dampers must react quickly and reliably, often triggered by heat or smoke detectors, then closing automatically without human intervention.

The quality of dampers matters greatly; those with multiple rotating blades, such as Mercor’s mcr WIP LD series, offer precise control over airflow while maintaining robust fire resistance.

Their rectangular casing design allows seamless integration in ducts of various sizes, which is essential for adapting systems across different buildings and requirements.

If smoke dampers form barriers, extract fans are the engines driving smoke out of the building. These fans generate a powerful and consistent airflow that pulls hazardous smoke away from people trying to evacuate and clears escape routes swiftly.

Unlike regular ventilation fans, extract fans in smoke control systems are engineered to operate under extreme conditions—high temperatures and heavy particulate loads—without losing performance.

Their durability and robustness cannot be overstated since they must function flawlessly when every second counts. Fans equipped with features such as high-temperature resistant motors and fireproof casings provide reassurance that the system won’t falter during emergencies.

In practical terms, this means the airflow stays uninterrupted even amidst thick plumes of smoke, helping to keep corridors and stairwells breathable and visible.

Behind the scenes, control panels serve as the command centre of the entire smoke ventilation system. Receiving inputs from an array of smoke detectors installed throughout the building, these smart devices decide when and how to activate dampers and fans.

This automatic response eliminates delays that could cost lives.

Modern control panels go beyond mere activation—they continuously monitor system health, logging faults or maintenance needs before problems arise.

Integrated solutions supplied by companies like Mercor can link into a building’s management system, giving facility managers real-time data at their fingertips.

This proactive oversight ensures that the system remains ready for action at all times and offers peace of mind that all components are functioning optimally.

Understanding these components sets the stage for exploring how regulatory frameworks shape their design, installation, and maintenance to meet critical safety standards. This next focus will help clarify the compliance requirements essential for effective fire protection systems in any building project.

In the UK, compliance with Building Regulations is not just a bureaucratic hurdle; it forms the backbone of safety in fire protection systems. Specifically, Approved Document B (ADB) sets out detailed requirements for fire safety in buildings, including extensive guidance on smoke control. These regulations mandate that mechanical smoke ventilation systems must be designed and installed in ways that reliably protect occupants by enabling safe evacuation routes and limiting smoke spread during a fire incident. Adhering to ADB ensures that systems perform as expected when every second counts.

Beyond simply meeting legal requirements, following such regulations means selecting components that are proven to operate correctly under fire scenarios. This isn’t a matter of guesswork or assuming that one size fits all — each building’s unique layout demands tailored design aligned with these standards. Therefore, compliance guarantees a holistic approach: from airflow calculations to component placement, ensuring full functionality. Without this framework, installations risk being ineffective or even dangerous.

There is ongoing discussion among industry professionals about whether current regulations keep pace with innovations in fire safety technology. Some critics argue the rules lag behind rapidly evolving mechanical ventilation capabilities, suggesting stricter or more expansive frameworks are necessary to address new architectural complexities, such as high-rise constructions or multi-use developments. Conversely, many experts emphasise that existing regulations coupled with verified products and professional design are sufficient if carefully applied, highlighting that over-regulation might stifle innovation and add unnecessary cost.

Regardless of these debates, one indisputable fact remains: using products certified by respected third-party bodies establishes an essential foundation of reliability and trustworthiness in your smoke ventilation system. Organisations such as the Loss Prevention Certification Board (LPCB) and British Standards Institute (BSI) rigorously test devices against stringent criteria covering performance, durability, and safety under extreme conditions. Choosing equipment with certifications from these entities—like Mercor Fire Protection UK’s range—ensures peace of mind through demonstrated compliance.

Certification doesn’t only speak to product quality but also supports smoother approval processes with building control authorities. Inspectors are familiar with LPCB or BS marks and often require such documentation before granting completion certificates. This streamlines project timelines and reduces costly delays.

Furthermore, certified systems benefit from technical support services informed by deep knowledge of regulatory demands—a valuable asset during design, installation, commissioning, and ongoing maintenance.

Over Mercor Fire Protection UK’s 40 years of combined experience via its global parent company, delivering certified solutions has been foundational. Sourcing products directly from our Manchester-based stock means swift access to trusted items compliant with UK law—and backed by full technical support from experienced professionals dedicated to client success.

Grasping these essential regulatory frameworks sets the stage for exploring how mechanical smoke ventilation systems function on a practical level—starting with the mechanisms that govern airflow control and distribution throughout a building’s critical spaces.

At the heart of any mechanical smoke ventilation system lies the challenge of moving smoke and heat safely and efficiently out of a building. Understanding the pathways that smoke follows—and how the system mechanisms support this—is crucial to designing a system that performs reliably in a fire event.

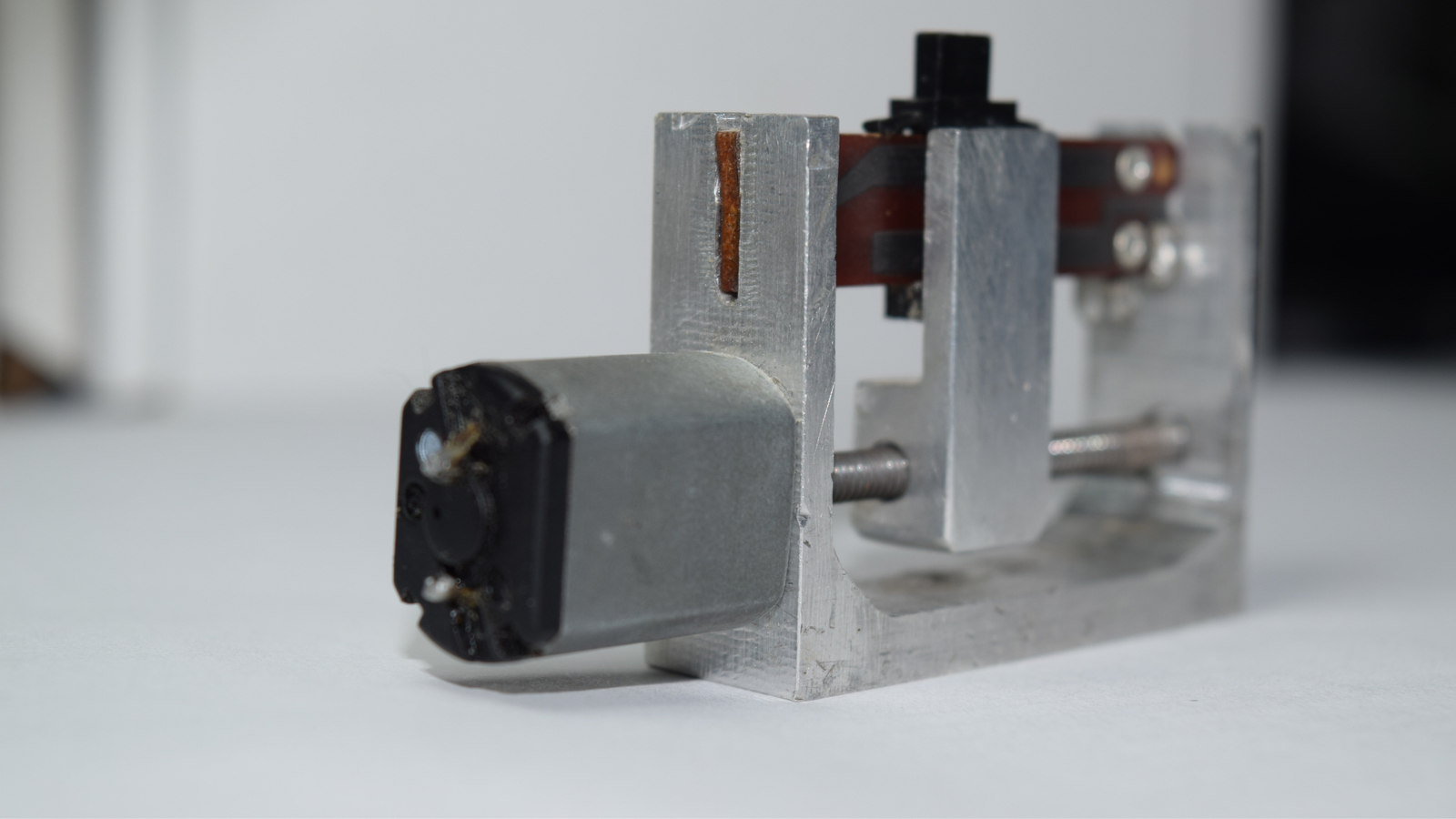

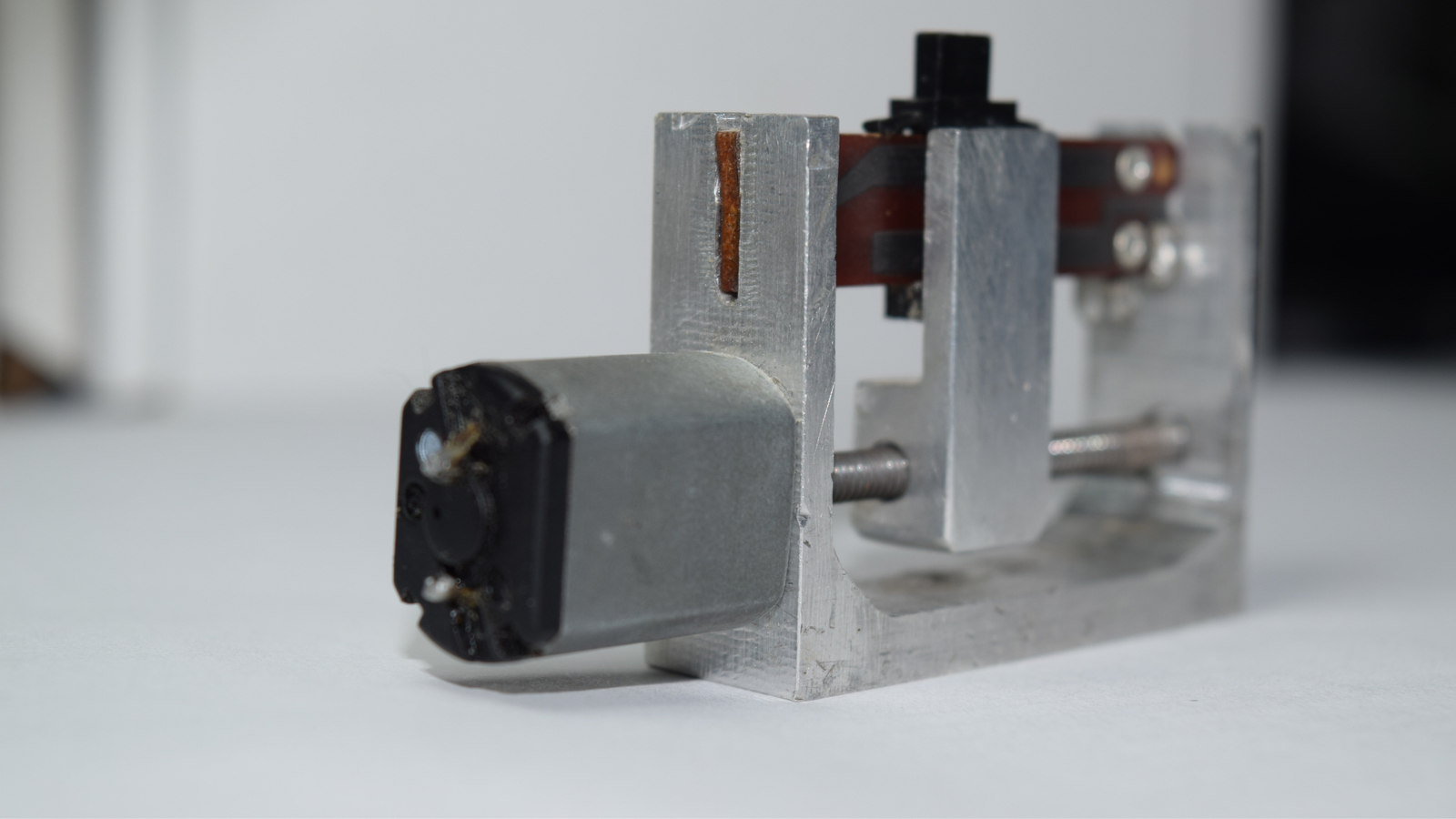

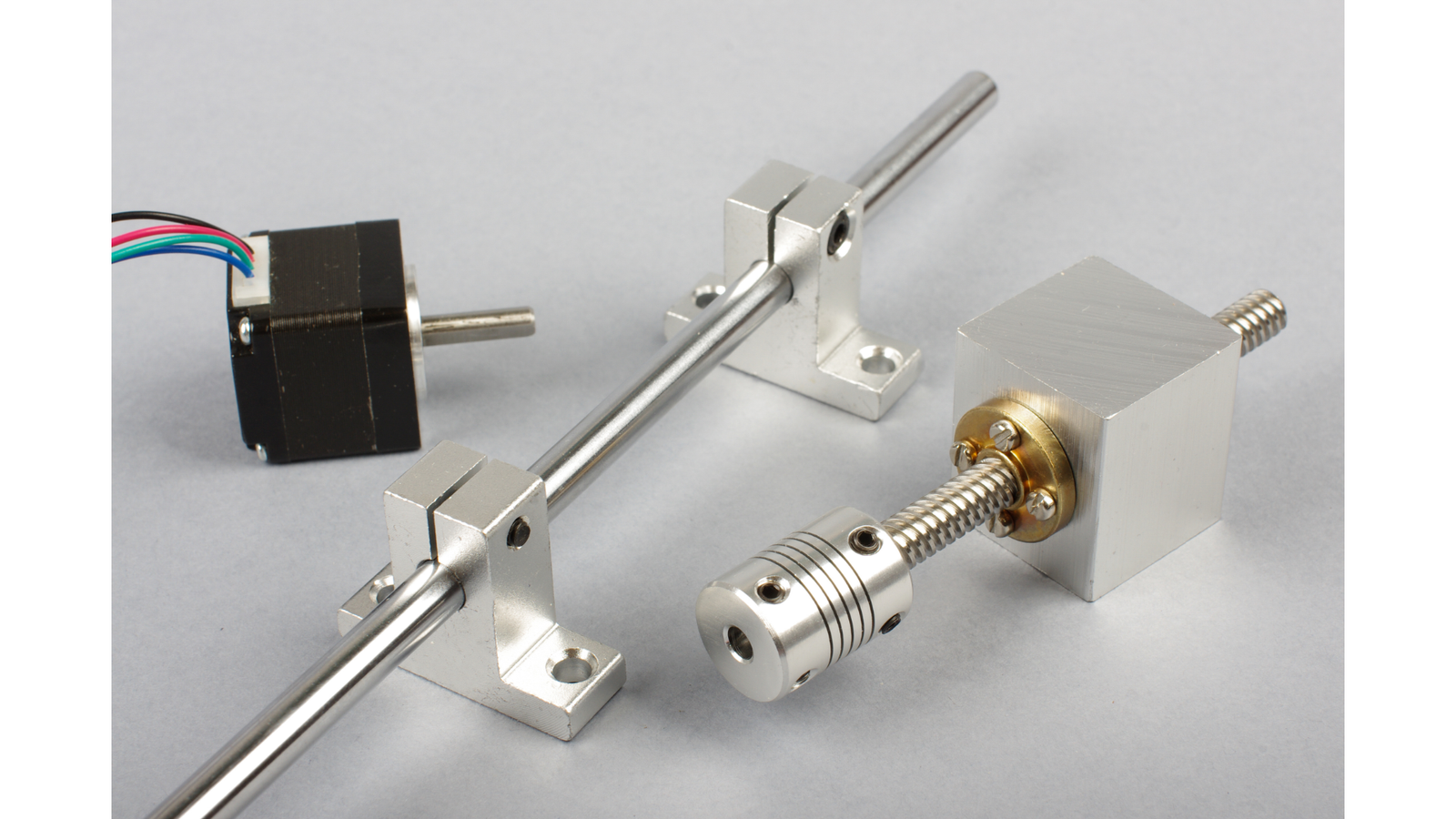

There are two fundamental approaches to drive airflow in smoke ventilation: active and passive systems. Active systems harness mechanical power—usually electric fans or actuators that open vents—to forcefully extract smoke from affected areas. These fans generate consistent airflow regardless of external conditions, making them especially reliable in complex buildings with intricate layouts or high occupancy levels.

On the other hand, passive systems lean on natural forces such as buoyancy, where hot smoke rises naturally through strategically placed vents, or pressure differences created by wind or temperature. While passive systems require less energy and maintenance, their effectiveness can fluctuate depending on weather or building configuration.

Given these distinctions, many modern designs opt for mechanical (active) smoke ventilation to ensure predictable control during emergencies. This reliability is not just a convenience but a critical component of occupant safety, keeping escape routes clear and reducing property damage.

Once the choice between active or passive systems is made, attention turns toward routing the airflow effectively within the building.

Smoke doesn’t just float aimlessly; it follows paths defined by architectural features and ventilation components. Typically, these pathways fall into three principal categories: vertical shafts, horizontal ducts, and roof openings.

| Pathway | Description |

|---|---|

| Vertical Shafts | Channels directing smoke straight upwards and out through roof or upper-level vents, leveraging natural buoyancy. |

| Horizontal Ducts | Move smoke sideways away from occupied spaces toward shafts or exhaust points; essential in sprawling floor plans. |

| Roof Openings | Positioned atop the building to allow smoke to exit vertically into open air; often include AOVs controlled remotely. |

The integration of these pathways must be carefully tailored to a building’s size and use. For example, stairwells often feature dedicated vertical shafts combined with lobby dampers to create protected escape routes free from smoke ingress.

Meanwhile, horizontal ducts might connect several rooms or compartments into one exhaust outlet to optimise ductwork efficiency without sacrificing performance.

From experience, incorporating both vertical shafts and horizontal ducts into the design rather than relying exclusively on one pathway type is highly effective. This dual strategy ensures multiple routes for smoke extraction, reducing pressure buildup inside compartments and enabling quicker clearing of hazardous fumes.

“A properly balanced network of airflow pathways is like giving smoke several exits instead of funnelling it through one congested door,” says our design engineers at Mercor Fire Protection UK Ltd., whose expertise informs each tailored system designed across the UK.

Beyond structural pathways, control mechanisms also play an essential role: actuators open vents at precise moments, fans adjust speed based on sensor feedback, and control panels synchronise all components to respond dynamically during fire events. This orchestration assures that smoke moves exactly where it needs to go—out of the building swiftly and safely.

Understanding these airflow mechanisms enhances not only system design but also informs ongoing operation and maintenance strategies critical throughout a building’s lifecycle. With this foundation laid, we can now explore principles guiding design choices and practical aspects of installation in greater detail.

Designing mechanical smoke ventilation systems is a precision-driven process that hinges on more than just placing fans and vents. At its core, it requires a deep understanding of the building’s architecture, the nature of its occupancy, and the specific fire hazards it faces. For instance, a bustling commercial space with large crowds demands a different approach than a quieter office environment or an industrial facility storing flammable materials. The smoke control zones you establish must align precisely with fire compartment boundaries to ensure that smoke can be effectively isolated and expelled without endangering escape routes.

This alignment is not guesswork but the product of advanced simulation tools. In professional practise, designers seldom rely just on theory; instead, they leverage sophisticated software that models smoke behaviour under various fire conditions. These simulations help pinpoint optimal vent placement, airflow rates, and damper operations, which is vital because even small miscalculations can compromise safety. Having nearly four decades of experience backing our approach at Mercor Fire Protection UK Ltd highlights the indispensable role of such technology in crafting reliable systems tailored for specific building profiles.

Every piece of the system—from smoke exhaust AOVs and lobby dampers to rooflights and control panels—must be selected not only for functionality but also for compatibility within the entire network. This ensures smooth communication between components and coordinated responses during an emergency. When specifying products like the mcr WIP LD range or mcr PROLIGHT roof vents, one must consider factors like free area size to meet required ventilation capacities without overwhelming noise or unnecessary power consumption.

Moving from design to installation, attention shifts quickly toward rigorous adherence to manufacturer guidelines. Installation is not simply about fitting parts together but guaranteeing accessibility for future inspections and maintenance. A system that is hard to service risks falling into disrepair, which defeats its purpose entirely. Ensuring clear paths around control panels, unobstructed access to actuators, and well-secured mounting of vents contributes directly to operational longevity.

The installation phase also involves thorough testing—verifying that dampers respond correctly to control signals, fans run at specified speeds, and smoke sensors trigger alarms as intended. It’s common for overlooking these final checks to lead to unexpected failures in an emergency, so meticulous documentation of tests provides peace of mind both for installers and building managers.

Post-installation best practises include scheduling regular maintenance visits complemented by performance monitoring—services Mercor UK offers—to detect any drift from optimal operation before problems arise. User-friendly interfaces on control panels simplify these tasks while reducing human error during routine checks.

With design and installation completed meticulously, the focus naturally shifts toward preserving system functionality through consistent upkeep and swift resolution of any issues that arise.

Proper maintenance is not just a recommendation—it’s essential to preserving the effectiveness and longevity of any mechanical smoke ventilation system. Think of it like caring for a car: if you never check oil levels or listen for odd noises, you risk a sudden breakdown. The same principle applies here. Regular care ensures that when an emergency arises, your system performs exactly as designed, protecting lives and property.

Monthly inspections are a cornerstone of keeping these systems reliable. During these checks, every component—from smoke detectors to control panels—needs careful visual and functional inspection. It’s not enough to just glance over; you have to verify that each part is clean, securely connected, and communicating properly with the rest of the system. For instance, sensors can accumulate dust or debris, which dulls their sensitivity, so wiping them down carefully without damaging sensitive electronics becomes critical.

Functional testing is just as important. Running test cycles for the fan units and control panels lets you catch faults early—sometimes what looks like a quiet day can hide subtle mechanical wear or electrical glitches. Take fans as an example: any grinding noise or sluggish response may indicate worn bearings or motor issues that would escalate if ignored. Similarly, software calibration in modern systems requires periodic verification and updates to maintain responsiveness and compatibility with evolving standards.

Keeping ducts and fans clean prevents blockages that can handicap airflow during critical moments. Dust accumulates quickly in ventilation pathways, much like leaves in a gutter after autumn storms. Even slight restrictions can reduce exhaust capacity or cause unbalanced airflow patterns, compromising smoke clearance effectiveness. Cleaning should be done with appropriate tools—compressed air or vacuuming—to avoid damage while removing all buildup efficiently.

“Regularly scheduled maintenance is not just about compliance; it’s about peace of mind,” as experts often say at Mercor Fire Protection UK.

Occasionally, you will run into common issues like fan failures, sensor malfunctions, or control panel errors. These problems might be intimidating at first glance but most follow similar diagnostic steps: isolate the affected component, check power supply integrity, review error codes on control panels, then move to physical inspection and reset procedures. Resolving these quickly prevents downtime and keeps your safety system fully operational.

One distinct advantage of working with Mercor Fire Protection UK is the access to full technical support available both online and by phone during business hours (8 am–5 pm). Their team can guide you through troubleshooting efficiently with expert advice tailored to your particular setup—saving you time and reducing uncertainty.

| Maintenance Task | Frequency | Key Action Points |

|---|---|---|

| Visual Inspection | Monthly | Check sensors, cables, housings for damage |

| Functional Testing | Monthly | Activate fans, test control panel responses |

| Cleaning | Quarterly or As Needed | Clear ducts/fans of dust and deposits |

| Software/Calibration Check | Annually | Verify controller firmware & sensor calibration |

Staying consistent with these steps will elevate your system’s performance from adequate to exceptional. It also reduces long-term costs by catching minor fixes before they grow into expensive repairs or replacement parts.

Mastering routine upkeep lays the groundwork for maximising fire safety outcomes within your building environment—an objective reached more effectively when proactive measures are combined with refined system designs.

Mechanical smoke ventilation systems are effective when designed and maintained properly, but their protective power can be substantially increased by integrating advanced technologies. One of the most impactful upgrades is the incorporation of smart sensors that continuously monitor smoke levels, temperature, and airflow. These sensors provide real-time data, allowing the system to react swiftly and adapt its ventilation output dynamically rather than relying solely on manual activation or preset triggers. This means quicker clearance of smoke and safer evacuation routes during an emergency.

Equally important is investing in certified, high-quality products from reputable manufacturers like Mercor Fire Protection UK. Using components that meet rigorous standards not only ensures compliance with UK fire regulations but also drastically reduces the risk of equipment failure when it matters most. For example, Mercor’s range of multi-blade smoke ventilation dampers, such as the mcr WIP LD 1.0 GFA, offers proven reliability paired with efficient smoke extraction capabilities. Selecting trusted suppliers can mean the difference between a system that works flawlessly under pressure and one vulnerable to breakdowns.

To keep pace with evolving fire safety standards and technological advancements, regular updates to your system’s hardware and software are essential. This includes scheduling periodic professional inspections to verify that all components function optimally and integrating new modules or control panels as they become available. Additionally, providing specialised training for maintenance personnel empowers them to manage complex systems confidently, troubleshoot issues proactively, and perform preventative care effectively. Mercor supports this through CPD training courses designed specifically for fire protection professionals.

As one building manager overseeing a large commercial property experienced first-hand: upgrading their facility with a Mercor mechanical smoke ventilation system halved their emergency response time. This improvement delivered tangible peace of mind—not just for occupants but also for the management team tasked with ensuring robust safety measures.

Beyond immediate operational benefits, this layered approach fosters resilience in your fire protection strategy. A well-maintained, intelligently controlled ventilation system acts as a reliable first barrier against the spread of smoke and toxic gases, buying critical time for evacuation and firefighting efforts alike.

| Enhancement | Benefit | Impact on Safety |

|---|---|---|

| Advanced Sensors & Automation | Immediate detection & adaptive response | Faster smoke clearance |

| Certified High-Quality Products | Reduced failure risk & regulatory compliance | Reliable operation under stress |

| Regular Updates & Training | System longevity & skilled maintenance | Maintains peak performance |

| Professional Support | Expert troubleshooting & guidance | Minimises downtime |

Finally, partnering with a knowledgeable supplier like Mercor Fire Protection UK ensures access not only to state-of-the-art equipment but also ongoing technical support. Their Manchester-based team is readily available to advise on bespoke solutions tailored to your building’s configuration and compliance requirements. Leveraging such expertise can transform your mechanical smoke ventilation from a basic safety feature into a finely tuned safeguard engineered for maximum effectiveness.

With these enhancements in place, your system won’t merely respond to emergencies—it will actively contribute to reducing risks within your building environment, reinforcing occupant safety at every turn.

Investing in advanced mechanical smoke ventilation solutions from trusted providers like Mercor Fire Protection UK significantly elevates fire safety and operational reliability. To explore tailored systems designed for your needs or request expert guidance, visit Mercor Fire Protection UK’s quote page and request a quote today.

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Choosing the right actuator for your fire protection systems may seem straightforward at first just pick a size and type

UK mainland delivery

Stock on hand in our UK warehouse

Online and phone support

Safe online payment options