What Is an Actuator? Definition, Types, and Applications Explained

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Smoke is often the most dangerous part of a fire, making it hard to see and breathe while trying to escape. That’s where automatic smoke ventilation systems come in—they quietly sense trouble and swiftly clear smoke from buildings before people even realise what’s happening. Understanding how these systems work and why they matter can make a huge difference in keeping people safe during emergencies. In this article, we’ll explore the benefits, technical details, and regulations behind automatic smoke ventilation, unlocking the simple yet powerful ways these systems protect lives and property.

Automatic smoke ventilation systems are designed to detect and expel smoke and heat automatically during a fire, improving occupant safety by maintaining clear escape routes and reducing toxic exposure. These systems comply with UK fire safety regulations and typically include components such as automatic opening vents, smoke control dampers, and control panels to ensure rapid smoke extraction and minimise property damage.

At their core, automatic smoke ventilation systems are designed to act swiftly and efficiently the moment smoke is detected. They rely on a network of sensors, control panels, and actuators all working in unison to clear smoke and protect building occupants.

When smoke detectors pick up even trace particles—typically within less than 30 seconds—they immediately alert the system’s control panel. This control unit processes the signal and triggers vents or windows to open, usually within the next 10 to 20 seconds, allowing smoke to escape naturally or be pulled out mechanically.

The timing here is critical: rapid detection and response improve visibility and reduce toxic inhalation risks. During a fire emergency, smoke can accumulate rapidly and obscure exits, complicating evacuation efforts and hampering firefighters’ visibility. By automatically opening vents high on roofs or walls, these systems create natural airflow paths that guide smoke upward and out before it becomes overwhelming.

To better understand how smoke is moved efficiently, we must look at the three primary modes these systems use:

The simplest mode relies entirely on natural airflow. Vents or windows automatically open when triggered, allowing warm smoke—lighter than air—to rise through openings near a building’s roof. This technique doesn’t involve mechanical fans but instead uses carefully engineered vent placement to harness pressure differences inside the building.

For example, Mercor’s mcr PROLIGHT AOV roof vent exemplifies this approach by providing ample free area (around 1.5 square metres) for rapid smoke release.

In buildings where natural draught alone isn’t sufficient—such as large commercial complexes—mechanical ventilation takes over. Powerful extract fans activated alongside vent openings draw smoke aggressively out of corridors or lobbies while fresh air inlets balance pressure inside. This controlled circulation prevents smoke from spreading laterally and helps maintain positive pressure zones protecting escape routes.

Hybrid systems blend both approaches to tailor response based on fire size or location. For instance, a fire starting in a lobby might prompt natural vent openings initially, then engage mechanical fans if conditions worsen. This versatility ensures optimal performance regardless of building layout or fire dynamics.

Recognising the strengths and applications of each mode enables engineers and safety officers to specify suitable systems that comply with regulations like EN 12101-2 while maximising occupant safety.

Furthermore, integration with existing fire alarm systems guarantees synchronised activation during emergencies. Actuators built into vents or dampers respond reliably—within 15 to 30 seconds—to commands ensuring consistent operation even during power failures thanks to backup batteries or generators.

“Automatic smoke ventilation is one of those unseen heroes in fire protection — working silently until every second counts.”

In practise, regular maintenance is equally essential to preserve this life-saving reliability. At Mercor UK, we emphasise timely inspections and functional tests to make sure components—from sensors through actuators—perform flawlessly when needed most.

This operational understanding highlights why selecting a quality system from an experienced provider like Mercor Fire Protection UK Ltd matters—not only do they deliver compliant products stocked locally for prompt delivery but their solutions embody nearly four decades of expertise tailored specifically for challenging UK building environments.

Having established how these systems operate to safeguard lives and property, it becomes crucial to examine the key components that make this sophisticated coordination possible. Understanding these parts brings clarity to their vital functions within fire protection strategies.

At the heart of every automatic smoke ventilation system lies an intricate collaboration between parts designed for speed, precision, and resilience. Let’s start with smoke detectors, the vigilant sentinels of fire safety. These sensors use advanced technology—often photoelectric or ionisation methods—to discern real smoke particles from innocuous mist or steam. This capability minimises false alarms, which can cause unnecessary panic or costly disruptions. When smoke is detected, it sends an instant signal to the system’s control panel.

The control panel acts as the central command hub. It processes input from multiple detectors, evaluates thresholds, and then triggers the ventilation mechanisms in less than five seconds—a critical window when every moment counts during a fire. Modern control panels also incorporate backup battery supplies that maintain operation during power failures, and many now offer remote monitoring features allowing building managers to stay informed about system status in real time.

Once the control panel signals an emergency, ventilators come into play—the physical gateways for smoke to escape. Roof vents or louvre windows are strategically placed to promote natural draught smoke extraction and maintain safe air quality inside. For instance, the Mercor mcr LAM Roof Louvre provides a generous free area of 1.13m², optimising airflow for rapid smoke egress while meeting stringent British standards. These design details ensure smoke doesn’t accumulate at occupant level, reducing inhalation hazards and improving visibility during evacuation.

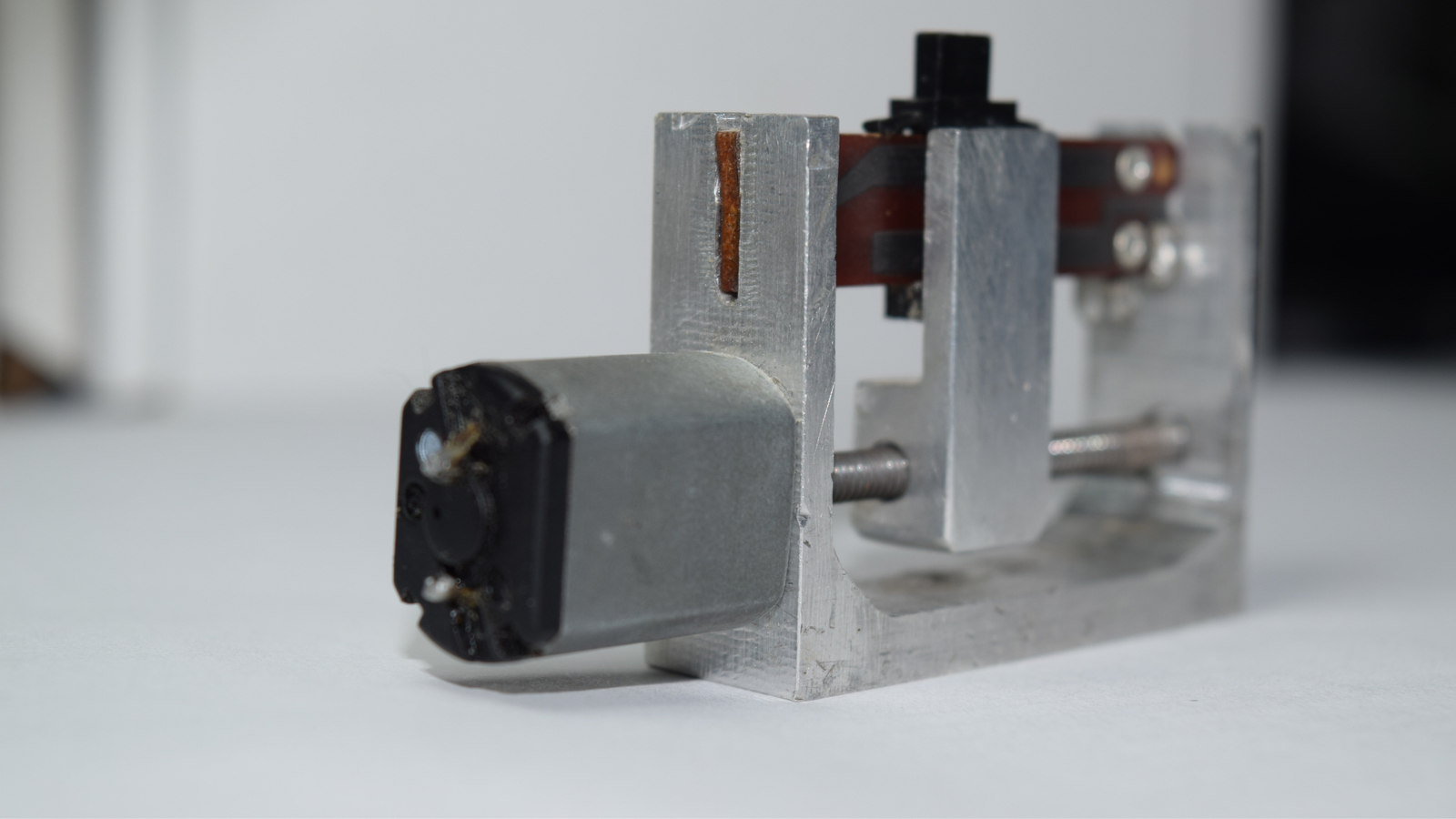

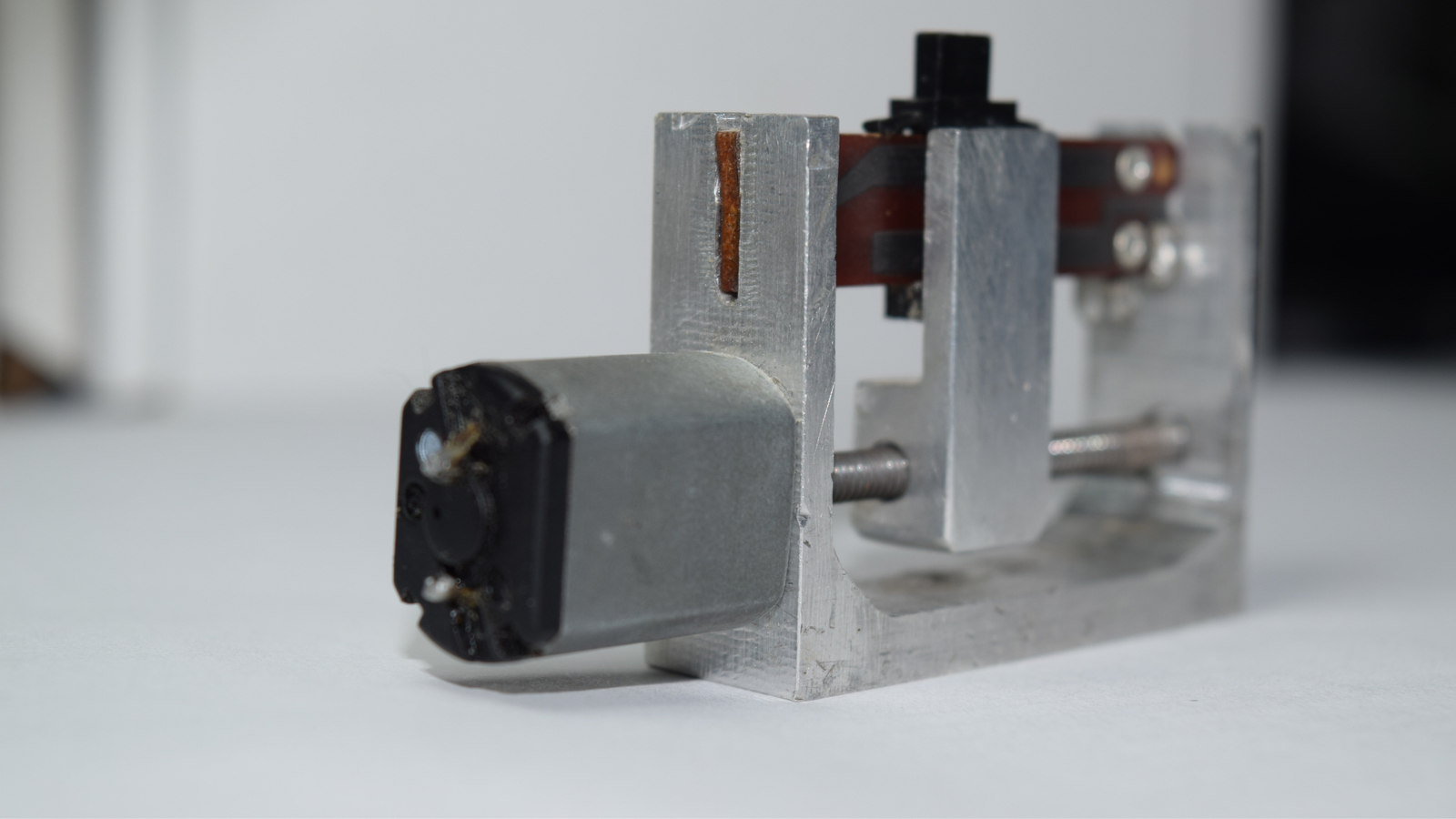

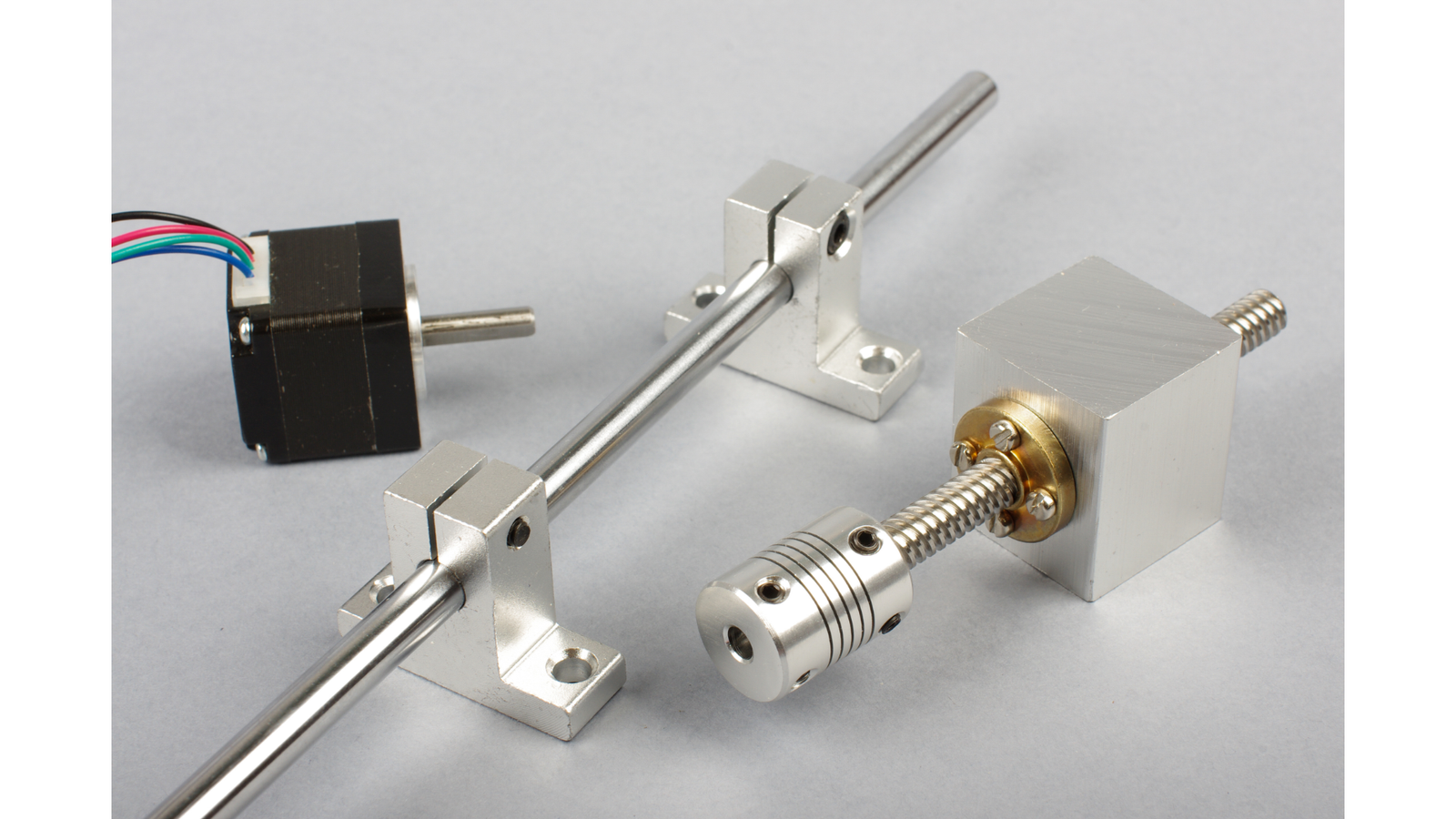

Complementing this is the role of actuators, often electric motors designed to open vents swiftly and reliably under harsh fire conditions. In Mercor systems, actuators deliver consistent performance thanks to robust engineering that withstands heat and potential debris interference during an incident. Their ability to operate automatically without manual input guarantees that smoke ventilation activates even if occupants cannot intervene.

| Component | Function | Key Feature |

|---|---|---|

| Smoke Detectors | Detects smoke presence | Differentiates fire smoke vs. steam |

| Control Panels | Central processing unit managing signals | Backup power & remote monitoring |

| Ventilators | Physical openings for smoke release | Large free area (e.g., 1.13m² for mcr LAM) |

| Actuators | Mechanically open/close vents | Heat-resistant electric operation |

Understanding these elements individually illuminates why choosing high-quality products and ensuring their integration is essential for safeguarding lives and property. Each component must perform flawlessly on its own but harmonise seamlessly with the others under pressure.

Building on this technical foundation, we can next explore how these systems provide life-saving advantages and comply with regulations shaping fire safety standards across the UK.

When a fire breaks out, the swift removal of smoke is not just a comfort—it’s a critical lifeline. Automatic smoke ventilation systems do far more than simply open vents; they actively create safer conditions by pushing smoke and toxic gases out of a building. This significantly enhances visibility during evacuations, allowing occupants to find exits more rapidly and avoid disorientation caused by thick smoke. Firefighters, too, gain invaluable advantage, as clearer air means faster search and rescue efforts with reduced exposure to hazardous fumes.

The safety improvements translate directly into lives saved and injuries prevented. Studies reveal that buildings equipped with these systems experience about 30% fewer casualties in fire incidents. This is no small statistic—it underscores how vital timely smoke extraction is during the critical moments of an emergency.

Beyond the immediate life-safety aspect, automatic smoke ventilation plays a pivotal role in protecting the building itself.

Fires don’t just threaten lives; they wreak havoc on structures. High heat coupled with dense smoke creates an environment where materials degrade rapidly, leading to costly repairs or even total loss. By reducing smoke temperature by up to 50% and lowering toxic gas concentration, these ventilation systems can slow destructive processes substantially. Think of it like opening windows to let steam escape while cooking—but magnified millions of times over in urgency and scale.

This reduction in heat and smoke limits damage to masonry, electrical wiring, and interior finishes. Studies suggest that buildings outfitted with efficient smoke ventilation can reduce fire-related repair costs by 20-40%. For property owners or managers, this means substantial savings while preserving valuable infrastructure.

Regulatory frameworks across the UK increasingly recognise these benefits as essential components of modern fire safety strategy.

Many commercial buildings, healthcare facilities, schools, and public spaces are now mandated by law to instal automatic smoke ventilation systems. This reflects growing awareness that passive fire protection alone isn’t enough. Mercor Fire Protection UK Ltd understands these evolving requirements well, offering products that seamlessly align with regulations like those set out by NFPA and UK building codes.

Compliance not only ensures legal conformity but often leads to financial incentives such as lowered insurance premiums—typically ranging from 15-25%. The logic is straightforward: insurers view buildings equipped with reliable smoke control as lower risk for extensive damage or casualty claims.

| Benefit | Impact | Data Point |

|---|---|---|

| Enhanced Safety | Faster evacuation and safer firefighter operations | 30% reduction in casualties |

| Damage Minimization | Less heat and toxic exposure reduces structural harm | Up to 50% lower smoke temperature |

| Regulatory Compliance | Meets laws, reduces liability and insurance costs | Insurance premiums cut by 15-25% |

Understanding these critical advantages sets the stage for exploring how correct installation and regular maintenance keep automatic smoke ventilation systems functioning optimally when they matter most.

Installation is the foundation of any effective automatic smoke ventilation system. Engaging certified professionals isn’t just a recommendation; it’s essential. Only qualified experts can ensure that every component—from actuators to control panels—is installed in strict compliance with UK fire safety regulations and standards like EN 12101-2 and NFPA 92.

This professional touch prevents common pitfalls such as poorly sealed vents, which can lead to dangerous smoke leaks during a fire. A well-executed installation also means your system integrates seamlessly with existing fire alarms and building layouts, maximising performance when every second counts.

Before any hardware goes up, conducting a thorough site survey is indispensable. This survey identifies the best locations for smoke detectors and automatic opening vents (AOVs), balancing aesthetic considerations with functional efficacy.

For instance, roof vents should be positioned where they can rapidly exhaust rising smoke without obstruction. Lobby dampers must align with airflow paths to prevent smoke from infiltrating protected escape routes. Skimping on this step risks compromising evacuation safety and even voiding manufacturer warranties.

After all components find their right place, maintenance takes over as the guardian of continued reliability.

The journey doesn’t end once installation wraps. Regular inspection and testing are critical to keeping the system ready for action at any moment. Industry guidelines recommend bi-annual visual inspections paired with an annual full functional test encompassing everything from actuator responsiveness to control panel diagnostics.

These maintenance routines reduce failure rates dramatically—studies show adherence to recommended schedules cuts breakdowns by nearly one-third. Given that smoke vent malfunctions have been linked to increased fire casualties, this preventative approach is not optional; it’s a mandatory life-saver.

Practical upkeep tips include verifying power supplies, checking seals on vents for air-tightness, and ensuring the electric actuators open and close smoothly within specified timeframes.

Additionally, integration points like sensors tied to fire alarms should be tested under simulated conditions to validate rapid response triggers. Keeping detailed logs during each service visit helps track wear patterns and anticipate part replacements before breakdowns occur.

At Mercor UK, we understand these complexities deeply and offer full technical support tailored to your system’s unique needs. Whether you require assistance designing a maintenance schedule or emergency repairs, our experienced team is available online or by phone to ensure your smoke ventilation installations remain compliant, effective, and ready when needed most.

Mastering both installation and upkeep turns your automatic smoke ventilation system into a resilient shield during emergencies. This foundation sets the stage for exploring how regulatory frameworks cement these safety measures into industry practises.

Automatic smoke ventilation systems aren’t just technical installations; they are governed by a detailed framework of regulations designed to ensure they perform reliably during a fire event. In the UK, the most authoritative guidelines come from the Building Regulations, specifically Approved Document B (Fire safety), which mandates that buildings such as commercial premises, high-rise apartments, and public spaces must have properly designed smoke ventilation systems to keep escape routes free of smoke.

This requirement isn’t incidental—it’s about preserving lives by facilitating safe evacuation and enabling fire services to operate efficiently.

These regulations specify system types appropriate for building height and occupancy. For instance, natural smoke ventilation using Automatic Opening Vents (AOVs) suffices for buildings up to 30 metres tall, relying on the principle of buoyancy to clear smoke.

However, buildings exceeding that height require mechanical smoke extraction systems employing fans that create pressure differences for effective smoke removal.

Such nuances are critical: installing the wrong type of system risks non-compliance, putting occupants at risk and exposing building owners to legal liabilities.

Additionally, British Standards like BS7346-8 focus on the design, installation, and maintenance of smoke control systems, while BS9991:2015 addresses fire safety in residential buildings with updated guidance on smoke ventilation from 2024.

Compliance with these standards means meticulous attention to component choice—from fire-resistant cabling and certified actuators to control panels meeting DesOps cause-and-effect functions—and integration with alarm and sprinkler systems.

On top of national regulations, components must meet product standards such as the BS EN12101 series.

The CE or UKCA marking under Construction Products Regulations confirms this compliance. These certifications assure that each element in the smoke ventilation system has passed rigorous testing for fire resistance and operational reliability under emergency conditions.

But what does this mean practically?

Besides being a legal obligation, adhering to these standards ensures your system works exactly when needed—opening vents automatically or activating fans according to precise inputs from smoke detectors integrated with fire alarms.

It also safeguards against faulty manual overrides or conflicting operations in multiple zones through mechanisms like primary zone lockouts.

Beyond safety, compliance also carries tangible business benefits. A certified and well-maintained smoke ventilation system increases your building’s market value by signalling robust fire safety protocols to tenants, insurers, and regulators alike.

It reduces potential liability by demonstrating due diligence in protecting occupants—a critical factor given how insurance claims escalate when non-compliance contributes to damage or injury during fires.

“Ensuring your automatic smoke ventilation system meets all relevant standards isn’t simply about passing inspections—it’s about creating a resilient environment where people can trust their safety even in worst-case scenarios.”

Navigating this intricate framework is essential not only for meeting legal requirements but also for enhancing overall firefighting effectiveness and occupant safety. From here, attention turns toward how these smoke ventilation systems seamlessly connect and function alongside existing fire protection measures within a building’s infrastructure.

Integrating automatic smoke ventilation systems within the framework of existing fire alarm and sprinkler systems transforms a building’s fire protection into a finely tuned safety network. This isn’t just about hooking one system onto another; it’s about creating a harmonious communication ecosystem where every component—from smoke detectors to dampers to control panels—works in sync to protect lives and property.

At its core, successful integration hinges on compatibility. Modern smoke ventilation solutions, such as those offered by Mercor Fire Protection UK Ltd, are designed to easily interface with prevalent fire alarm control panels (FACPs). This is achieved by adhering to standardised communication protocols like BACnet or Modbus. These protocols are crucial because they translate signals between different devices, ensuring that when a heat sensor rings an alarm, the smoke vents instantly open without delay.

Roughly 85% of contemporary FACPs support these protocols, making integration more straightforward than ever.

When specifying or retrofitting a smoke ventilation system, it’s vital to confirm upfront that your chosen products comply with local codes and can seamlessly interact with your existing detection and suppression systems. Compatibility reduces the risk of signal failures that could otherwise result in delayed vent activation or false alarms—both costly and dangerous outcomes.

Another game-changing advantage comes from utilising centralised control panels tailored for smoke ventilation management. Imagine having a single dashboard that not only receives alerts but also manages vent actuation, monitors system status, and provides maintenance feedback in real-time.

This centralised approach allows emergency responders and building managers to have clear visibility into smoke movement and system performance. It also facilitates quicker decisions and manual overrides if needed.

By consolidating data streams from multiple sensors and actuators into one intuitive interface, mass confusion during stressful situations is significantly reduced.

The evidence supporting these integrated systems is compelling. Statistics underscore that integration can reduce smoke clearance time by an average of 30% compared to standalone ventilation setups.

Such improvement means occupants get clearer visibility sooner, lowering inhalation risks and accelerating safe evacuation.

Furthermore, maintenance becomes more manageable as test cycles synchronise across all components. Regular inspections seldom miss communication faults because systems self-report via these interfaces—translating into fewer unexpected failures during actual emergencies.

Regulatory frameworks increasingly mandate such integration. In Europe, EN 12101-10 requires intercommunication between mechanical smoke control components and fire alarm systems, while NFPA standards emphasise annual testing of fully integrated configurations.

Non-compliance can jeopardise insurance coverage and place occupants at increased risk.

In this regard, Mercor’s UK-stocked range adheres rigorously to recognised standards such as UL 864 and EN 54 for product certification—ensuring peace of mind alongside prompt availability.

Designing your fire safety strategy around integrated smoke ventilation aligns cutting-edge technology with regulatory demands, setting the stage for practical implementations that save lives during emergencies. Next, we explore how these systems perform in real-world environments where theory meets critical action.

Practical deployments of automatic smoke ventilation systems reveal how theory transforms into safety in moments that matter most. Consider a multi-story office building in London, where Mercor’s automated system was installed throughout the floors. During a minor fire, the system sprang into action immediately—ventilating smoke efficiently and directing it away from escape routes.

This wasn’t just a technical success; it allowed occupants to evacuate calmly without panic or confusion. The consequences were profound: the property sustained only minimal smoke damage, and importantly, there were zero casualties. This case underscores how vital prompt smoke extraction is in preserving both lives and assets when every second counts.

What makes this performance notable is not just the technology itself but how well it meshes with the building’s layout, occupant density, and emergency protocols. Smoke control isn’t simply about pulling air out—it’s about managing smoke flow so clear paths remain for safe egress.

This requires precise calibration of airflow rates tailored to the space’s unique architecture and functionality, something Mercor specialises in through rigorous design backed by Computational Fluid Dynamics simulations and field data.

Moving from commercial spaces to healthcare facilities offers another layer of insight.

In a major UK hospital, an advanced roof louvre ventilation system was implemented specifically for emergency smoke control. Hospitals pose an exceptional challenge due to vulnerable patients and complex internal layouts that slow evacuation.

Trial runs during fire drills demonstrated remarkable improvements—not only did the air quality within affected zones stabilise faster, but staff reported smoother patient movement to safety. Such results highlight how ventilation systems serve more than regulatory checkboxes; they actively shape outcomes where seconds define life-or-death scenarios.

A hospital environment demands relentless reliability since mechanical or natural ventilation must perform flawlessly despite plug loads, medical equipment, and possible obstructions. Hybrid systems pairing natural buoyancy-driven vents with mechanical fans can activate under different conditions to optimise energy use and efficiency—a balance increasingly prioritised within performance-based fire protection design.

“Automatic smoke ventilation is a silent yet essential hero in protecting fragile lives during emergencies,” a safety officer reflected after observing several drills supported by such systems.

These tangible successes emphasise lessons that go beyond individual sites.

They serve as evidence that investing in automatic smoke ventilation isn’t merely about compliance but about smart risk management fortified by cutting-edge technology. Regular maintenance schedules aligned with operational needs ensure these systems remain ready for unexpected events—turning theoretical designs into practical safeguards.

| Aspect | Key Insight | Benefit |

|---|---|---|

| System Responsiveness | Immediate activation upon fire detection | Minimises smoke exposure and supports rapid evacuation |

| Integration Flexibility | Adapts to diverse building types | Ensures suitability whether office, hospital, or industrial site |

| Energy Efficiency | Hybrid models optimise power use | Balances safety needs with operational costs |

| User Confidence | Enables orderly evacuations | Reduces panic and ensures occupant safety |

Understanding these dynamics allows building managers, architects, and fire safety professionals to make better-informed decisions reflecting not only legal mandates but real-life human factors at play during emergencies. For companies like Mercor operating at the forefront of fire protection solutions in the UK, each project is an opportunity to tailor systems that protect people first while respecting environmental and economic considerations.

If you’re responsible for fire safety planning or facility management, consider how automatic smoke ventilation fits within your broader strategy. Assess your building’s unique architectural challenges and occupancy patterns before selecting between natural, mechanical, or hybrid ventilation options—and engage experts who leverage simulation tools alongside field experience to design effective solutions.

As fire protection technologies evolve, so does our ability to prevent tragedy rather than just respond to it—cementing automatic smoke ventilation as essential infrastructure in modern buildings.

Investing in advanced automatic smoke ventilation systems is not only crucial for legal compliance but fundamentally protects lives and property when emergencies strike. For tailored solutions designed for your building’s specific needs, request a quote today at Mercor UK.

Automatic smoke ventilation systems are typically installed in areas like atriums, stairwells, corridors, and large open spaces where smoke can accumulate rapidly during a fire. Their strategic placement ensures effective smoke extraction, improving visibility and air quality for occupants and firefighters—studies show that proper ventilation can reduce smoke levels by up to 70%, significantly enhancing evacuation safety.

Automatic smoke ventilation systems should be inspected and maintained at least twice a year to ensure optimal performance, as dust accumulation and mechanical wear can significantly impair their functionality when seconds count. Fire safety authorities often mandate these biannual checks, citing that over 40% of smoke ventilation failures occur due to neglected maintenance — which is hardly a statistic you want your building to top!

Automatic smoke ventilation systems trump manual ones by kicking into action the moment fire strikes—no human fumbling required—significantly slashing smoke inhalation risks and improving evacuation times. Studies show that automatic systems can reduce smoke buildup by up to 70%, boosting visibility and cutting rescue efforts by nearly half. Plus, they tirelessly monitor conditions 24/7, ensuring safety doesn’t take a coffee break, unlike manual systems that rely on quick reflexes under stress.

Automatic smoke ventilation systems are like savvy firefighters with super-sensitive noses—they detect smoke or heat through sensors such as smoke detectors and thermal sensors, triggering vents to open and release smoke promptly. This swift response can reduce smoke inhalation risks by up to 50%, greatly improving evacuation safety and limiting fire damage. Essentially, they turn smoky chaos into clear air, helping save lives and property without you lifting a finger.

An automatic smoke ventilation system is essentially a well-choreographed dance of components: smoke vents or skylights that pop open faster than your morning blinds, smoke detectors acting as vigilant sentinels, control panels orchestrating the show, and sometimes even powerful fans pushing the smoky curtains aside. Together, they can reduce toxic smoke levels by up to 70%, giving occupants precious minutes to escape and firefighters clearer visibility—proving that in a fire, speed and coordination truly save lives.

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Choosing the right actuator for your fire protection systems may seem straightforward at first just pick a size and type

UK mainland delivery

Stock on hand in our UK warehouse

Online and phone support

Safe online payment options