What Is an Actuator? Definition, Types, and Applications Explained

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Smoke is one of the biggest dangers during a building fire—it can quickly fill rooms, making it hard to see and breathe safely. Natural smoke ventilation systems offer a smart way to deal with this threat by using simple airflow principles to let smoke escape through vents and windows, helping people find their way out while keeping the air clearer. This guide breaks down how these systems work, what makes them effective, and why they play a key role in keeping buildings safer without relying on complex machinery or electricity.

Natural smoke ventilation systems are designed to automatically open vents, such as rooflights or windows, to extract smoke and heat during a fire, improving visibility and air quality for safe evacuation. These systems enhance occupant safety by reducing smoke inhalation risk and maintaining breathable air, complying with UK building regulations and standards for effective fire protection.

At the heart of any natural smoke ventilation system are Smoke and Heat Exhaust Vents (SHEVs). These vents play a critical role by opening automatically when fire is detected, creating an escape route for smoke and hot gases that would otherwise accumulate indoors. This venting reduces temperature and toxic smoke levels, significantly increasing occupant safety and visibility during evacuation. You’ll often find these vents installed as roof-mounted Automatic Opening Vents (AOVs) or wall-mounted shutters, designed to integrate seamlessly with the building’s structure while adhering to stringent safety standards like EN 12101-2.

The design of these vents takes into account not just immediate fire response but also environmental factors — wind load resistance, material durability, and operational reliability in extreme conditions. For example, Mercor’s mcr PROLIGHT E series includes roof vents with free areas up to 1.5 m², optimising airflow without compromising structural integrity. Having these vents strategically placed ensures maximum efficiency in smoke extraction when seconds matter most.

Complementing the vents are the control panels, often described as the ‘brains’ behind the entire operation.

These panels constantly monitor signals from multiple detectors throughout the building and activate the ventilation system instantly upon detecting smoke or heat. An advanced model like Mercor’s mcr PRO-Servo offers precise management capabilities, ensuring smooth coordination between sensors and actuators under varied scenarios. Besides just triggering vent openings, many control panels offer manual override functions for safety personnel, diagnostic reporting for maintenance staff, and seamless integration with existing fire alarm or building management systems (BMS).

The sophistication in control panel technology today permits automatic adaptations based on environmental feedback — such as adjusting opening angles depending on wind speed or varying fire intensity. This dynamic adjustment is crucial because a static vent position might not optimally clear smoke or may even worsen airflow patterns inside complex buildings.

Of course, no system functions without accurate sensors and detectors feeding it information promptly and reliably.

Sensors form the sensory organs of an NSVS, scanning continuously for early signs of fire through smoke density, rising heat levels, or combined indicators like carbon monoxide presence. Modern multi-sensor detectors leverage these combined technologies to reduce false alarms—an important aspect to maintain trust in automated safety systems. With detection ranges often covering around 30 square metres per sensor, proper placement throughout key building zones guarantees timely responses.

Additionally, environmental monitoring sensors can be integrated to enhance system responsiveness—for instance, wind sensors that adjust vent operation to optimise smoke exhaust against prevailing outdoor conditions. Proper calibration of these devices is vital; too sensitive and the system risks unnecessary activations, too insensitive and detection speed suffers.

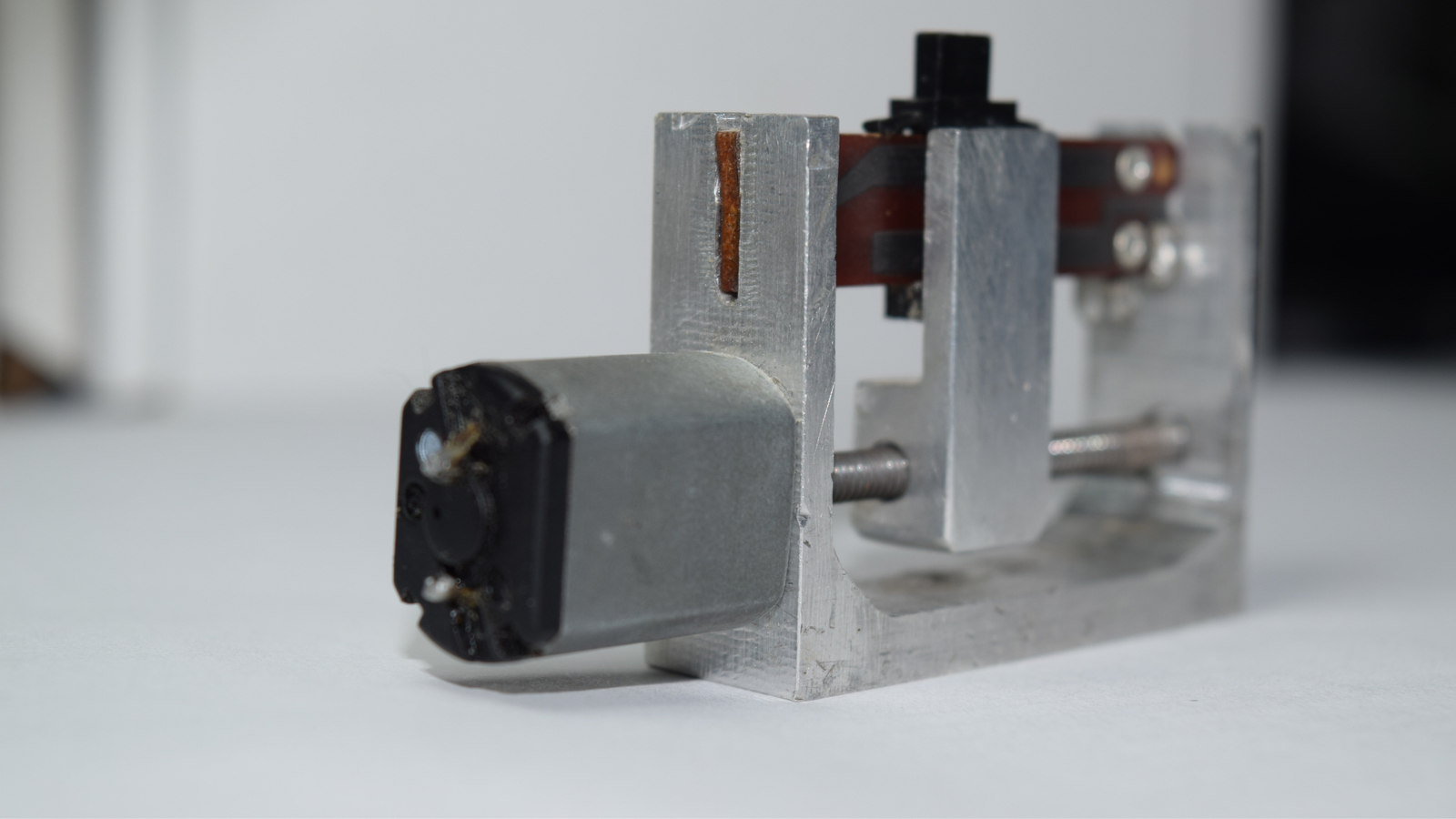

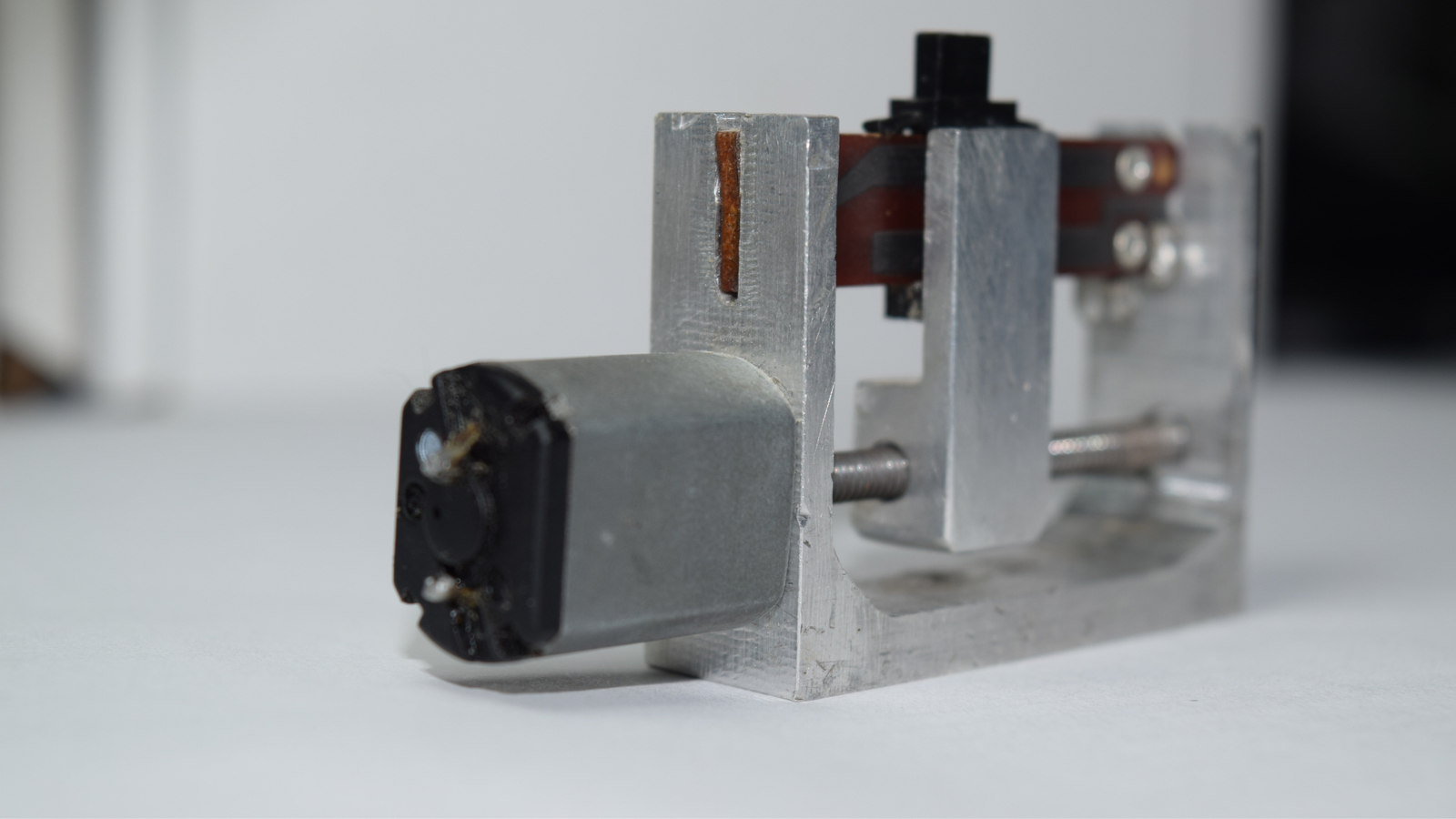

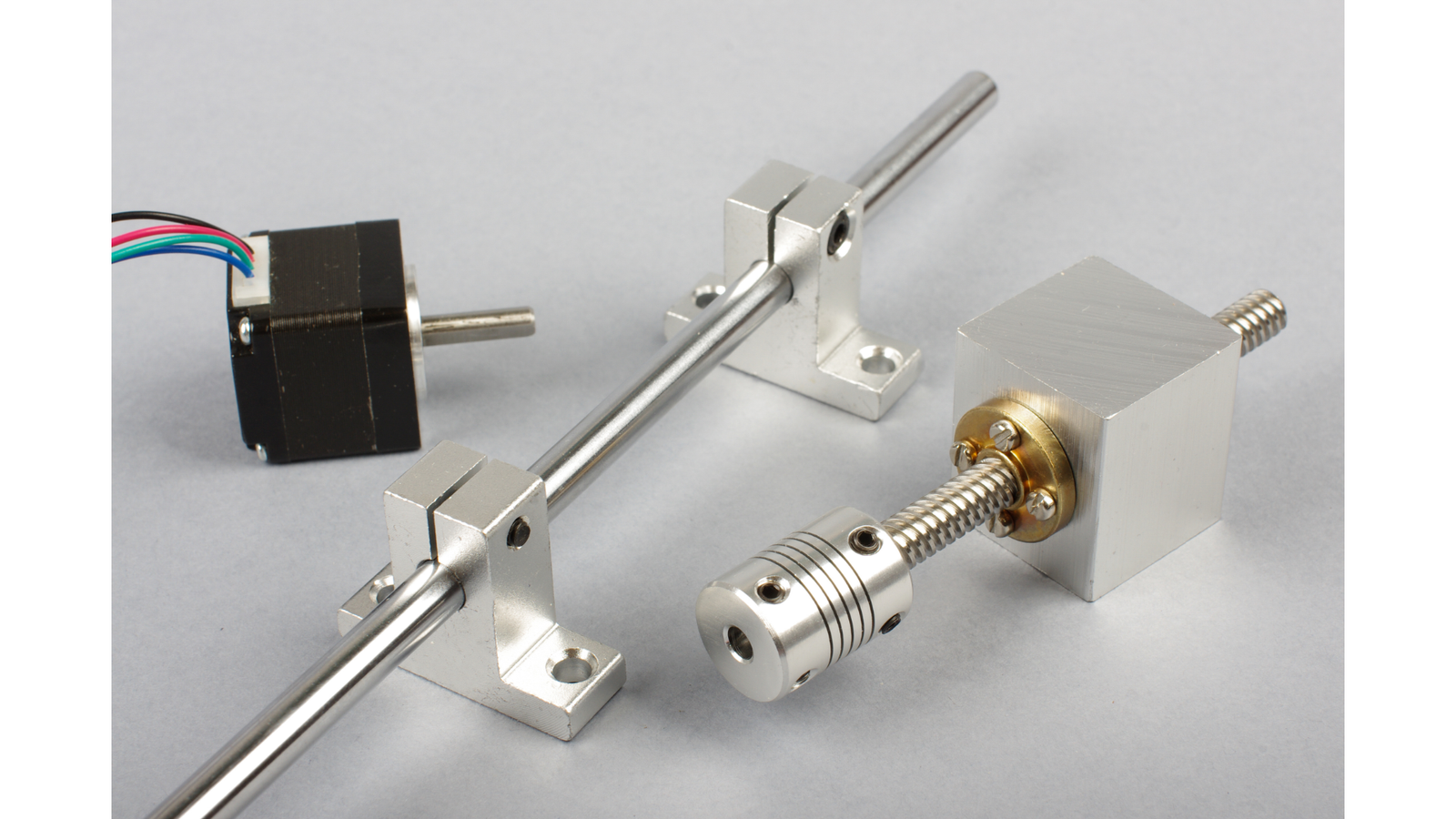

Once detection triggers a response, actuators take over as the physical mechanism driving vent operation.

Actuators convert electrical or pneumatic power into mechanical movement, opening or closing vents with precise force and speed tailored to system requirements. Electric linear actuators are common for their reliability and ease of control, offering stroke lengths sufficient for typical vent sizes while operating within standard temperature conditions (-20°C to +60°C). Alternatively, hydraulic or pneumatic actuation systems might be selected for installations demanding higher force output or specific environmental tolerances.

Choosing the right actuator involves balancing factors like installation environment, required opening speed (some vents need to open fully within seconds), load capacity to withstand wind pressures, and long-term durability under weather exposure. High-quality actuators ensure vents perform flawlessly when called upon—a non-negotiable in life-critical systems.

Together, Smoke and Heat Exhaust Vents, Control Panels, Sensors, Detectors, and Actuators create a finely tuned network that rapidly reacts during fires to safeguard lives and property by efficiently ejecting smoke and hazardous gases before they overwhelm occupants.

Understanding these components individually sheds light on their interconnected functionality. Each part depends on others working flawlessly—it’s this orchestration that transforms natural smoke ventilation from a passive concept into an active defender in a building’s fire safety strategy.

Having mapped out the essential elements within such systems, we can now explore how these components operate collectively during a fire event to protect lives and property effectively.

At its core, natural smoke ventilation relies on a basic thermodynamic principle: hot air rises. When a fire starts inside a building, it produces hot smoke and gases that naturally rise towards the highest points—usually ceilings or roof areas. This buoyancy-driven movement creates convection currents that can be directed outward through specially designed vents or rooflights.

Once heat and smoke accumulate beneath the ceiling, sensors detect the increase in temperature and activate the system’s control panel. This triggers automatic opening of vents or rooflights, creating a clear exit path for smoke and hot gases. The result is an immediate reduction in smoke concentration at occupant level, improving visibility and air quality during evacuation. Think of it as opening a window when a room fills with smoke, but with far greater precision and effectiveness.

Because this process relies entirely on natural forces rather than mechanical fans, it brings several practical advantages—especially in emergencies.

By eliminating reliance on powered extraction units, natural smoke ventilation systems cut down energy usage significantly. They also sidestep risks associated with electrical failures during fires—a critical benefit since power loss is common in such events. Moreover, fewer moving parts mean less ongoing maintenance, lowering long-term operational costs.

To maximise their effectiveness, vents should be installed at high points where heat and smoke gather fastest. Proper placement ensures that natural airflow harnesses the stack effect most efficiently, rapidly clearing smoke from protected spaces.

Buildings that incorporate ample roof vents combined with well-placed windows or other openings support these convection currents beautifully. This thoughtful design not only enhances safety during fires but can improve everyday indoor air quality by naturally refreshing interior environments.

| Aspect | Explanation |

|---|---|

| Principle | Hot air and smoke rise due to lower density |

| Activation | Heat detectors trigger vent opening |

| Vent Placement | High points like roofs or ceilings |

| Energy Usage | Minimal—no mechanical fans needed |

| Maintenance | Lower due to fewer mechanical components |

| Safety Benefit | Functions reliably even during power outages |

Understanding these fundamentals reveals why natural smoke ventilation represents not just an elegant use of physics but a practical strategy ensuring safer building environments without excessive complexity or cost.

Having explored the mechanics and benefits of natural smoke ventilation, we now shift focus to how these systems play an essential role within the broader context of fire safety strategies.

NSVS systems play a vital role in safeguarding lives and property during fire emergencies. These aren’t just technical installations; they form a frontline defence that actively reduces risk. According to the Fire Protection Research Foundation, effective smoke control can reduce fatalities by up to 50% during building fires—a significant statistic that highlights the life-saving impact of these systems. By controlling smoke and heat early, NSVS create safer conditions for everyone inside.

One of the most critical ways these systems enhance safety is through improving evacuation conditions. Smoke is often more dangerous than the flames themselves because it obscures vision and contains toxic gases. When rooflights or vents open automatically under smoke detection, they rapidly remove smoke from escape routes, dramatically increasing visibility. This improved clarity allows occupants to find exits faster and evacuate more safely. As a result, many buildings equipped with NSVS experience significantly reduced evacuation times—sometimes up to 40% faster, according to multiple fire incident analyses.

Beyond visibility, these systems also moderate the spread of heat and toxic gases. Lower smoke concentrations effectively slow fire progression, assisting firefighters by reducing temperature and hazardous gas accumulation in stairwells and corridors. Experimental data from the UK’s Building Research Establishment revealed that NSVS can lower ambient temperatures in escape routes by approximately 30°C compared to non-ventilated scenarios—an invaluable difference that enhances firefighter entry and occupant survival chances.

And while protecting people is paramount, these systems offer powerful benefits in preserving infrastructure as well.

Fires often cause devastating damage—not just from flames but also from intense heat and penetrating smoke. Natural smoke ventilation minimises this damage by swiftly exhausting hot gases and smoke, which are primary contributors to structural degradation and costly repairs. Historical case studies consistently demonstrate that buildings fitted with NSVS sustain markedly less damage than those without them. This mitigation can mean saving thousands or even millions in reconstruction costs after a fire event.

The reduction in soot deposits and acidic residues—which result from incomplete combustion—helps prevent erosion of masonry joints, corrosion of metalwork, and deterioration of finishes inside buildings. For commercial properties especially, minimising repair expenses translates directly into business continuity benefits and lower insurance premiums.

A safety manager from a high-rise corporate office in Manchester shared their experience:

“Installing natural smoke ventilation systems has given us peace of mind. It’s reassuring to know there’s an extra layer of protection for our employees — not only do we comply with regulations easily, but we have practical safety mechanisms that really work.”

Investing in NSVS aligns with legal mandates such as EN 12101-2 compliance, which governs system performance standards across Europe and ensures designs maintain minimum extraction rates to optimise safety outcomes. At Mercor Fire Protection UK Ltd, we emphasise rapid supply from UK stock combined with comprehensive technical support so your system is installed correctly and ready when you need it most.

“Natural smoke ventilation doesn’t just save lives; it saves entire buildings.”

Understanding this importance provides a strong motivation for building owners, architects, and safety consultants alike to prioritise NSVS integration both at design stages and during upgrades to existing facilities. The risk mitigation alone justifies making these systems a cornerstone of modern fire protection strategies.

Having established why these systems matter so much for safety and preservation, it’s essential to explore how their design integrates seamlessly into buildings’ architecture and operational plans going forward.

Incorporating Natural Smoke Ventilation Systems (NSVS) during the initial design phase doesn’t just add a layer of safety — it ensures that smoke and heat can be managed seamlessly if a fire occurs. The decisions made here influence everything from occupant safety to code compliance and the overall efficiency of smoke extraction.

One essential architectural consideration is designing spaces that support natural smoke movement. High ceilings and open atriums create an environment where hot smoke rises unimpeded, collecting near the roof where roof vents can then exhaust it quickly. This strategy leverages the natural buoyancy of hot air, minimising the accumulation of dangerous smoke layers at lower levels where people move and evacuate.

In modern architecture, this principle has evolved into sophisticated features like double-skin facades paired with large atria. Such designs aren’t merely aesthetic; they serve an important function by facilitating precise airflow paths for smoke evacuation. These architectural choices reflect a shift towards blending safety considerations with innovative building forms — proving that fire protection can harmonise with design creativity.

While architects set the stage, the technical precision needed to position and calibrate NSVS components comes from a close collaboration with fire engineers.

Partnering with experienced fire engineers allows designers to simulate potential fire scenarios virtually before construction begins. Through these simulations, heat and smoke behaviour within various building zones can be predicted, revealing optimal locations for installing Automatic Opening Vents (AOVs) or rooflights.

This collaborative process ensures that vents open swiftly and effectively within seconds of fire detection, meeting stringent response times specified by standards like EN 12101-10. Together, architects and engineers fine-tune vent sizes and placement based on factors such as floor area coverage and maximum travel distances for occupants, key components that establish safe evacuation routes.

This partnership also addresses integration challenges — ensuring NSVS works alongside HVAC systems without compromising positive pressure zones or causing unwanted airflow interference. It’s a balancing act between mechanical systems and natural ventilation strategies, ultimately designed to maximise both building comfort and fire safety.

Beyond technical design, legal requirements provide the foundation that guarantees these efforts meet standardised criteria acknowledged across jurisdictions.

Compliance with regulations such as EN 12101-2 is not optional; it’s fundamental to certifying that NSVS installations achieve necessary performance benchmarks. This European standard outlines key metrics including minimum vent opening areas—generally one twentieth (5%) of the served floor space—and specifies required materials capable of maintaining integrity under fire conditions for minimum durations, such as an EI30 fire resistance rating.

Moreover, local building codes often demand NSVS in large public or commercial spaces exceeding certain thresholds — typically open-plan areas over 200 square metres or atria in office complexes.

Meeting these codes means more than ticking boxes; it translates into practical benefits for occupants. Properly sized vents positioned at high points allow for swift expulsion of toxic fumes and heat, reducing risks of smoke inhalation during emergency evacuation. Routine maintenance and testing obligations accompany these standards, ensuring ongoing system readiness long after installation.

“Good design marries safety with compliance — it’s this synergy that makes natural smoke ventilation systems effective in real-world scenarios.”

Besides thoughtful building design and regulatory adherence, measuring the real-world performance of NSVS remains a vital step to ensure their intended lifesaving function operates reliably day after day.

Measuring the effectiveness of a Natural Smoke Ventilation System (NSVS) is far more complex than simply checking if vents open during a fire event. Real-world performance depends on several interlinked factors—how quickly smoke clears from a space, how well temperatures drop, and how much visibility improves for occupants evacuating a building or for firefighters entering. These metrics define whether an NSVS truly enhances safety or just offers theoretical protection on paper.

For instance, studies indicate that a well-designed NSVS can clear up to 85% of smoke from a compartment within 5 to 8 minutes, dramatically improving air quality and lowering hazardous temperatures. Such performance is vital because smoke inhalation causes the majority of fire-related injuries, and rapid clearing increases chances of safe evacuation. Moreover, using a system aligned with EN 12101-2 standards ensures uniform assessment criteria, helping specifiers and installers deliver predictable results.

To gauge these metrics accurately, modern evaluations combine field testing with cutting-edge computer modelling. Physical smoke tests simulate fire scenarios in controlled environments, measuring variables like airflow rate and temperature gradients. However, real fires are unpredictable—wind changes, building occupancy, and ventilation obstructions all influence outcomes. This is where simulation tools come in as indispensable aids.

Software such as the VELUX Daylight Visualizer is often employed not only for daylight analyses but also for simulating smoke movement and exhaust efficiency in natural ventilation systems. By creating detailed 3D models of building spaces including rooflights or Automatic Opening Vents (AOVs), engineers can predict how smoke behaves under various conditions long before construction begins. These simulations grant insights impossible to capture via physical tests alone, allowing optimisation of vent placement and control strategies to maximise smoke clearance rates.

Across numerous UK commercial projects monitored by Mercor Fire Protection UK Ltd., simulation projections closely matched measured performance post-installation—validating their reliability. For example, in high-rise office buildings fitted with mcr PROLIGHT E roof vents, both simulated airflow rates (around 1.5 to 3 m³/s per vent opening) and achieved smoke layer height reductions confirmed design effectiveness swiftly enough to aid occupant safety without mechanical assistance.

Confirming that theoretical and practical performance align paves the way for another critical stage: ensuring compliance with fire safety regulations — an essential element for both legal adherence and overall building risk management.

Building codes and fire safety regulations serve as the backbone for the safe design, installation, and operation of natural smoke ventilation systems. Without adherence to these rules, even the most sophisticated system risks failure during an emergency, which defeats its fundamental purpose: protecting lives and property.

In Europe, one of the most important standards guiding NSVS is EN 12101-2. This regulation sets out mandatory performance criteria specifically for natural smoke and heat exhaust ventilators. It doesn’t just suggest best practices—it demands rigorous testing and validation of every component used in the system. This means fans, vents, actuators, and controllers must reliably perform under extreme conditions to clear smoke efficiently from escape routes.

Compliance with EN 12101-2 is more than a bureaucratic box to tick. It guarantees that every piece of equipment meets high safety and durability benchmarks, minimising surprises during critical moments. Importantly, this standard enforces regular testing after installation—ensuring the system retains its functionality over time. Neglecting these inspections can allow subtle issues like mechanical wear or sensor faults to compromise safety.

Keeping up with EN 12101-2 doesn’t just protect occupants; it also shields builders and owners from legal liabilities associated with non-compliance.

The key to smooth compliance is integration from the earliest stages of building design. Retrofitting a smoke ventilation system at the end of construction often leads to expensive modifications or suboptimal placements of vents and ducts. Conversely, collaborating with fire protection engineers familiar with EN 12101-2 at the planning phase allows for seamless inclusion of NSVS that both meets legal requirements and fits naturally within architectural aesthetics.

The importance of aligning with regulations extends beyond Europe. For instance, recent updates in California’s building codes emphasise natural smoke ventilation tailored to wildfire risk areas, creating a growing demand for systems designed with meticulous regard to evolving regulations.

Taken from industry leaders like Mercor UK and partners such as VELUX, many products are specifically engineered to comply fully with EN 12101-2. These solutions streamline installer confidence because they’ve undergone strict certification processes. Using certified components simplifies approvals by building inspectors and insurance assessors alike—a benefit that often goes overlooked until projects reach critical phases.

Compliance doesn’t end once installation wraps up. Regulatory bodies increasingly demand documented evidence of ongoing maintenance and functional verification. Implementing a robust maintenance schedule guarantees that NSVS components continue fulfilling their life-saving roles without deterioration or error.

“Safety is truly a cycle—its success depends on design adherence, quality installation, and vigilant upkeep.”

To navigate these complex standards confidently, take advantage of detailed guidance available at Mercor UK. Their resources offer practical insights on aligning your project or facility with EN 12101-2 and other essential codes governing natural smoke ventilation systems.

Understanding compliance requirements opens the door to effective implementation strategies that keep systems operational and reliable. Next, we explore how these principles come alive through careful setup and routine care to maintain optimal performance over time.

Proper installation forms the backbone of any effective natural smoke ventilation system. The process begins well before a single vent is mounted—it starts with a thorough site assessment. This careful evaluation considers the building’s layout, airflow patterns, and potential fire risk zones to determine where vents and sensors will offer the greatest protection. Poor placement can mean slow smoke extraction, putting lives at risk and compromising evacuation routes when seconds count.

Once the plan is mapped out, technicians move on to installing vents, control panels, and detectors meticulously following manufacturer guidelines—such as those provided by Mercor UK—and local building codes. This ensures each component interfaces correctly within a unified system designed for swift smoke and heat removal. Vents must be positioned for optimal airflow while sensors need strategic locations to detect rising smoke early without false alarms. The control panel acts as the brain of the operation, so it demands professional installation alongside reliable electrical connexions to guarantee responsiveness during an emergency.

But installation is only half the story; regular maintenance plays an equally crucial role in system reliability.

Smoke ventilation systems cannot be treated as “fit and forget.” Instead, they require ongoing inspection and servicing to maintain peak performance. For example, control panels benefit from bi-annual testing to confirm functional status and communication pathways remain intact. Meanwhile, actuators and sensors demand quarterly checks since exposure to dust, moisture, or mechanical wear can hinder their sensitivity or movement over time.

Cleaning vents removes accumulations of debris that might obstruct smoke flow or reduce opening efficiency. Even a slight layer of grime can delay critical smoke evacuation by impeding the vent’s ability to open fully or speedily. Neglecting these tasks increases failure risk dramatically; studies show up to 30% of malfunctions relate directly to inadequate upkeep. Keeping a detailed maintenance log after every service session not only builds accountability but also aligns with fire safety audits needed for regulatory compliance.

To navigate these complex requirements confidently, consulting professionals like those at Mercor UK is invaluable. Their experts bring nearly four decades of experience delivering rapid installations across the UK alongside proactive maintenance programmes tailored specifically for your building’s architecture and usage patterns.

“We had our NSVS installed by Mercor UK, and their team was highly professional, ensuring our system is compliant and fully operational,” reports a satisfied client—testimony to the peace of mind skilled professionals provide.

| Component | Maintenance Frequency | Who Should Perform |

|---|---|---|

| Control Panels | Every 6 Months | Certified Technician |

| Smoke Detectors | Quarterly | Fire Safety Officer |

| Vents & Actuators | Quarterly | Building Engineer |

In essence, a well-installed and carefully maintained natural smoke ventilation system fuses engineering precision with routine vigilance—a partnership between technology and human expertise that guards occupants’ safety and preserves building integrity with every passing day.

Ensuring your natural smoke ventilation system is professionally installed and regularly maintained is critical to safeguarding lives and property. Request a quote today from Mercor UK to secure expert support tailored to your building’s needs.

Natural smoke ventilation systems, while ingeniously simple and energy-efficient, generally lag behind mechanical systems in effectiveness due to their reliance on wind and thermal buoyancy, which can be inconsistent; studies show mechanical systems can clear smoke up to 30% faster and maintain controlled airflows regardless of external conditions, making them more reliable for critical building safety—though nature’s breeze does win points for sustainability and cost!

Designing and installing a natural smoke ventilation system for optimal performance involves strategically placing vents and openings, typically at high and low points, to maximise the natural chimney effect, allowing hot smoke to rise and exit swiftly while fresh air enters. Key considerations include building geometry, wind patterns, and compliance with fire safety regulations like BS 7346-8 or NFPA standards. Studies show properly designed systems can reduce smoke temperature by up to 60%, significantly improving occupant safety and visibility during evacuation. Effective installation ensures airtight seals elsewhere, preventing smoke bypass and maintaining airflow integrity—because in fire safety, every puff counts!

Natural smoke ventilation systems are commonly used in large commercial buildings, warehouses, and industrial facilities where open spaces allow for effective smoke dispersion. They’re especially popular in buildings with high ceilings or atriums, as these designs facilitate natural airflow, reducing the need for energy-intensive mechanical systems. According to recent fire safety studies, over 60% of new warehouse constructions opt for natural smoke ventilation due to cost-effectiveness and compliance with stringent building regulations focused on occupant safety.

A natural smoke ventilation system is essentially a clever ensemble of smoke vents, natural air inlets, and control devices like actuators and sensors—all working together to whisk smoke out of buildings without the need for power-hungry fans. Think of it as nature’s own fire alarm system, using strategic openings (like roof windows or vents) at high points to let hot smoke escape, while fresh air rushes in from lower levels. According to the Fire Safety Journal, properly designed systems can reduce smoke layer heights by up to 75%, significantly improving occupant visibility and safety during a fire.

In the witty world of natural smoke ventilation, regulations like BS 7346-8 (UK) and NFPA 92 (US) are the superheroes ensuring smoke doesn’t throw a house party uninvited. These standards dictate clear design, installation, and maintenance protocols, crucial since studies show that effective smoke ventilation can reduce fire-related casualties by up to 50%. So, while letting smoke out naturally sounds like Mother Nature’s job, it’s really these regulations that keep buildings safe and cosy!

Actuators might not be a word you hear every day, but they’re everywhere, quietly making things move and work the

Choosing the right actuator for your fire protection systems may seem straightforward at first just pick a size and type

UK mainland delivery

Stock on hand in our UK warehouse

Online and phone support

Safe online payment options